TIG welding is one of the most precise and versatile welding methods. Anyone who regularly performs demanding TIG welding tasks is familiar with the typical practical challenges: often, the torch necks have to be changed when switching positions, materials, or dealing with hard-to-reach components. This not only leads to a loss of time but also increases the risk of inaccuracies and errors if the entire torch needs to be replaced. Modern interchangeable neck torches, such as the ABITIG® GRIP A T | W T, are specifically designed to address this need.

A must-have for tough TIG welding

Topics: TIG, manual welding

Laser triangulation in welding: How many lines does a sensor really need?

Have you ever wondered how you can optimize the quality of weld seams in series production? Are you annoyed by rejects or rework? If you use welding robots including laser triangulation in your production, for example, you know that precise welds are essential – not only for stability, but also for the efficiency and cost-effectiveness of your processes. There are different sensors available and the question is: how many lines are better for your application? A sensor with one or three lines?

Topics: Robotic Welding, Seam Tracking

When welding tolerances become a trip to hell

Poorly prefabricated components, problems with correct clamping, material distortion due to heat from the process ... very often it is a major challenge to meet the required position tolerances during welding. Does this sound familiar to you?

Topics: Robotic Welding

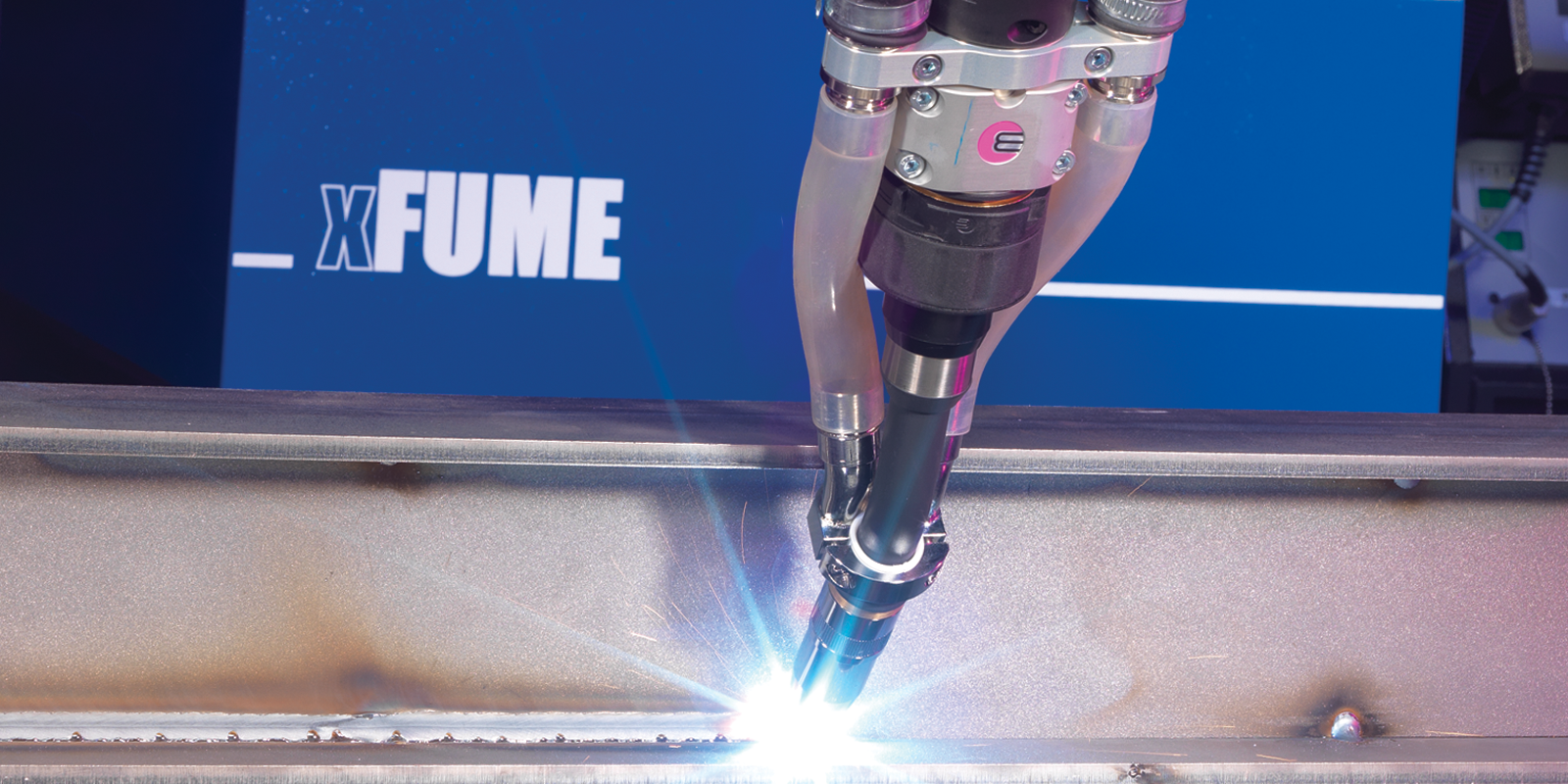

Extraction torches – the new standard in welding?

Have you ever passed the mandatory vehicle inspection even though the emissions were not right? Have you ever lit a cigarette in a restaurant in Germany in the last 15 years and waited to see the reactions? So why should you continue to weld without a fume extraction torch knowing how harmful welding fumes are to your health?

Topics: Fume Extraction

Welding fume extraction W3 – What you should know about it

Welding fume extraction is an important aspect in industrial manufacturing to control air quality and protect the health of employees. Welding fume class W3 is of particular importance. What is meant by this and who needs a welding fume extraction system with W3 certification?

Topics: Fume Extraction

Cobot vs. Robot – automation in welding

The question is no longer whether automation makes sense in the industry, but rather which type of automation is a better fit for welding – cobots or robots? While both technologies are capable of automating the welding process and thus increasing productivity, there are specific advantages and disadvantages that need to be considered when making a decision. In this blog post, we will look at the differences between cobots and robots in welding, highlighting factors to consider for effective automation of the welding process.

Topics: Robotic Welding, Automation

Welding procedures in aluminum processing

Electric cars, hybrid vehicles, modern transport systems for freight traffic – the future belongs to electromobility. More product functions mean more electronics, which in turn mean more weight for the designs. On the other hand, there are the legal regulations for reducing emissions, which can often only be complied with or fulfilled by reducing weight. One solution is the use of lightweight materials for constructions of modern transport systems, such as aluminum. But aluminum tends to be a bit of a "diva". You need very specific prerequisites and welding equipment to weld aluminum alloys properly. Process reliability is a top priority in aluminum processing.

Topics: Aluminum Welding

Why extraction is a must in TIG welding

TIG welding is considered to be a very clean welding process, as little or no welding fumes usually rise during work. But appearances are deceptive. Even though there are not much welding fumes generated, it is important not to underestimate the dangers of TIG welding. Because other factors also play a role and they make TIG extraction a good solution.

Topics: Fume Extraction, Health & Safety, TIG

How can I evaluate the potential savings of shielding gas?

The fact that saving gas in welding is possible without compromising the quality of the welding seam is not a secret anymore. A gas management system can regulate that there is always enough gas used for the welding application, while not using more than necessary. But how can companies evaluate the actual potential gas savings for their welding application before deciding to purchase a piece of equipment? No matter if it's manual or automated welding, the process is the same. Let's walk you through the process!

Topics: Gas Management

Save up to 50 % gas during gas-shielded welding

Horrendous electricity and gas bills, increasingly expensive food, unaffordable repair services ... the current situation is the number one topic of conversation with neighbours and in the media. As citizens, you save wherever you can and do without many things that used to be a matter of course. In industry, people are constantly looking for cost-cutting measures that must not, however, restrict production. Welding companies and other manufacturing companies that employ skilled welders are not exempt from this. Where can savings be made in welding if the quality of the products must not suffer under any circumstances? There is one approach that is often not recognised as a savings potential: shielding gas.

Topics: Gas Management

Pickling metal – which treatment is best?

Beautifully crafted railings and staircases made of stainless steel, high-gloss kitchen fronts or building facades that gleam in the sun from afar are already real eye-catchers. To turn a metal into an end product worth looking at, the surface must be treated accordingly. In metalworking, pickling is used in addition to grinding, brushing or blasting. There are different approaches to this, depending on the requirements in the production process.

Topics: Welding Chemicals

Optimising the service life of welding robots

In the two previous blogs on how to reduce downtime with welding robots, the focus was on the robot torch and its wear parts.

Topics: Robotic Welding

Downtimes due to wear parts during robot welding

In our first blog on how to reduce downtimes with robotic welding equipment, the focus was on robotic torches. We looked at the right choice of robot welding torch, torch power, torch geometry and highlighted that without “clean”' programming none of this will work.

Topics: Robotic Welding

How to avoid or reduce downtimes with welding robots

When it comes to high quantities, cost and time pressure, welding robots provide valuable assistance. With them, consistent quality can be achieved in the shortest possible time. However, productivity in automation or robotics also depends significantly on how often and how long a welding robot is at a standstill because it has to be reloaded, set up again after a crash or generally maintained. Every second of downtime counts and costs money. And it cannot be generalised who is more affected by downtimes in production: the group with large robot production lines or the small medium-sized company that only has one welding robot in operation. A welding robot in industry must function trouble-free as much as possible – and having the right equipment in production or in the company helps with this. Find out here how to reduce downtimes for welding robots.

Topics: Robotic Welding

Settings for gas-shielded welding: it’s that easy

The valve on the gas cylinder is turned open as far as possible so that gas flows sufficiently and a safe shielding gas coverage is ensured. Finally, the weld seam should be of good quality and besides ... gas is always there. In this way, day after day, litre after litre of shielding gas flows out of the gas cylinder into the working area, and thus into the environment, completely unnecessarily. At first glance, the gas manufacturer may be pleased with the high gas consumption of the customers, whereas the bank account of the producing company and the environment are not. However, it is so easy to reduce gas consumption through the appropriate gas setting in gas-shielded welding – and this applies to robot welding as well as to manual welding. Yes, that' s right: manual welders can also have the exact amount of shielding gas supplied automatically. And they can do this completely without a pressure regulator for shielding gas.

Topics: Gas Management

Which are the best gas nozzles for MAG welding?

Practical tips about all you need to know about gas nozzles for MIG/MAG torches

The MIG/MAG welding process is very demanding and both man and material are pushed to their limits? – often even beyond. Therefore, it is all the more important to work with good tools, especially the welding torch with its wear parts. These parts are very close to the process and have to withstand heat and weld spatter for as long as possible. Especially the gas nozzle, which, in addition to its actual task, is often misused as a hammer.

Topics: MIG/MAG

Is aluminum welding toxic?

When welding aluminum, as with all other weldable metals and metal alloys, emissions arise in the form of combustion and evaporation residues.

Which protective measures are suitable here and is aluminum welding toxic?

Topics: Fume Extraction

The 11 most frequently asked questions about fume extraction

When it comes to welding fume extraction, a couple of questions are frequently asked. Often it is about the performance, weight or handling of fume extraction torches, but also the service life of welding fume filters in extraction devices or the correct volume flow control are recurring topics.

Since welding fumes are toxic and the extraction of welding fumes should be mandatory to protect employees, we answer the most frequently asked questions about welding fume extraction and clear up common prejudices and concerns so that you can find the perfect solution for you and your welders.

Topics: Fume Extraction

Fume extraction for robotic welding – nice-to-have or must-have?

The fact that the welder is close to the welding process and would therefore be completely exposed to the dangerous gases in the welding fumes without a fume extraction system is no surprise. But how is the situation when using a robot for welding? Do similar precautions need to be implemented as with manual welding? Just as with manual welding, the dangers of welding fumes should not be underestimated.

Topics: Robotic Welding, Fume Extraction

Cause of weld spatter: GMAW welding and electric arc

Gas-shielded metal arc welding – also known as GMAW welding or MIG/MAG welding – is by far the most applied and most common welding process in welding technology. When searching for the cause of weld spatter, this process literally hits the bull's eye. Whereas with TIG welding and plasma welding almost no weld spatter occurs, spatter formation in GMAW welding can never be completely prevented. The question may arise why not use TIG or plasma welding in general if welding spatter should be avoided as much as possible. To get the answer it is necessary to take a closer look at the process of MIG/MAG welding and the cause of weld spatter.

Topics: Welding Chemicals

Anti-spatter agents: unbeatable, (non-)flammable?

Flammable vs. non-flammable anti-spatter sprays

Wherever welding takes place, weld spatter also occurs. During MIG welding and MAG welding, spatter formation is particularly high. Although it is possible to reduce the formation of weld spatter in these processes through process optimisation, it can never be avoided completely. Since weld spatter partially sticks, a good preparation is required, because it can be found almost everywhere: on and in the front end of the torch including the gas nozzle, on the contact tip and contact tip holder, on the workpiece as well as on the clamping element, if used. However, by applying a good sprayable anti-splatter agent, which is suitable for all areas, the majority of the welding spatter can be kept away or easily removed.

Topics: Welding Chemicals

5 mistakes to avoid with a fume extraction torch

Extracting harmful welding fumes should be standard in every manufacturing company for health reasons. Many rely on large extraction systems for extraction, which completely exchange all of the hall air within a very short time. More efficient and far cheaper than such large air filtration systems are extraction devices where appropriate fume extraction torches can be connected for source capture. With the fume extraction torches from ABICOR BINZEL, fume extraction is easy.

Topics: Fume Extraction

Advantages and differences of non-flammable anti-spatter agents

Whether it is an anti-spatter spray, a paste or an emulsion: anti-spatter agents for welding are available on the market in many variants - for using on the welding torch, on the work piece or even on both.

They all serve the purpose to avoid time-consuming rework by removing weld spatter from the work piece, to reduce downtimes due to frequent wear part changes, and to ensure that tools used in the welding process, such as clamping devices, always remain fully operational.

What role does it play whether an anti-spatter agent is flammable or non-flammable? Moreover, are all non-flammable anti-spatter agents equally good?

Topics: Welding Chemicals

Aluminum welding with a cobot – does that work?

7 practical tips for a neat weld seam

No question: aluminum welding is the premier class of welding. In a previous blog we explained in detail what a manufacturing company should pay attention to when welding aluminum by hand. But what do you do when the quantities are so high that one welder alone can no longer handle them? If hiring an additional welder for aluminum welding is not an option or you simply cannot find a suitable welding specialist? Can you possibly also weld aluminum in industry with a cobot – i. e. a collaborative robot – or is it too difficult to program a cobot to achieve the same results as when welding aluminum manually.

Topics: Robotic Welding

4 Things to Consider Before Automating TIG Welding

Is automated TIG welding economically viable?

When automating a TIG application, the first question to ask is the same as for any other automation: Is it profitable to use a robotic welding torch or a robotic welding cell?

Topics: Robotic Welding, TIG Torches

Dangers in welding – Why the welding torch shouldn´t become a burden

When you think of the dangers of welding, the usual suspects immediately come to mind: In addition to obvious things like harmful UV radiation during arc welding, sparks and welding spatter, or even hazards from electrical current, there are also the invisible dangers of welding, for example, by inhaling harmful welding fumes.

There are multiple ways to protect the welder from all these hazards: Wearing personal protective equipment (PPE) when welding is considered a matter of course and protects the skin and, above all, the eyes from radiation and injuries caused by welding spatter and flying sparks. Fume extraction torches, ventilated welding helmets or fume extraction systems can filter toxic welding fumes from the air and thus protect the welder's respiratory organs.

But how can welders protect themselves in the long term against damage to their musculoskeletal system? What helps against permanently tense muscles, signs of fatigue and back pain?

An often underestimated aspect of welding is the welding torch itself!

Topics: Welding Safety, MIG Guns & Torches, MIG/MAG, Health & Safety

With ABICOR BINZEL you’re on the way to a Green Factory

EWR 2 gas management system for welding: saves gas right from the start!

What makes a company a Green Factory? Everything that has to do with sustainability. Using renewable raw materials, grow organically, use of solar energy, save CO2 ... these are all approaches that can make our world a little better. One or the other can also be implemented in welding technology and fortunately it is becoming increasingly important for companies to do something to protect our environment. The trend is towards becoming a so-called Green Factory. ABICOR BINZEL can support you or your company on the way to the Green Factory. Or expand your status as a Green Factory.

Topics: Gas Management

Welding correctly with fume extraction torches: 3 practical tips

When welding metals, there are a number of emissions which, on the one hand, cause the legally prescribed MAK values (“maximale Arbeitsplatz-Konzentration”: maximum workplace concentration) to rise above the permissible threshold value and, due to toxic and / or disease-causing ingredients, represent a health risk for the personnel in the processing area. This fact obliges companies in the welding industry in particular to ensure effective air filtering and ventilation in the areas concerned. Because not only the welder himself is affected by the harmful emissions, but also the rest of the staff in the production hall, who are exposed to the welding fumes.

In addition to a large number of stationary fume extraction systems, the torch-integrated fume extraction (fume extraction torches) is one of the most effective and mobile methods that can be used. Welding with fume extraction torches is definitely a challenge when it comes to the handling.

So how can you weld correctly with fume extraction torches? What do you need to pay attention to?

Topics: Fume Extraction, MIG Guns & Torches

Welding with a robot – the 5 most common mistakes

The welding robot has been programmed for hours. The straight paths work perfectly, when welding a curve everything is wrong back and forth – what happened? The industrial robot is synchronized, the component is fastened and the weld seam is still set incorrectly – where is the mistake? On the first day, tens of components were perfectly welded, the next day the seam was displaced – how could that happen?

Topics: Robotic Welding

What you should consider with welding fume filters

Purchasing a fume extraction unit is the first step in the right direction. To protect the welder and other endangered persons from the dangers of welding fumes for as long as possible, there are a few things to consider, especially when it comes to the fume filters. The fume filter ensures that the hazardous gases in the welding fumes are filtered out and that the working environment is safe for everyone. How exactly does that work?

Topics: Fume Extraction

EWR 2: Reduce shielding gas consumption and save money now

Why shielding gas offers a huge savings potential

The valve is opened and there it is: the shielding gas for welding. Depending on the requirements of the welding task, the gas pressure and gas quantity are still set with the manometer before starting. Pre-flow time? Rather a little longer. Better safe, than sorry. The same applies to the post-flow time. Whether this lasts a few seconds longer or not does not seem to make much difference. Or maybe it does? The fact is: the shielding gas consumption is usually much too high. With the gas management system EWR 2 you can save money in gas shielded arc welding.

Topics: Gas Management

Practical tips for welding: sharpening tungsten electrodes

5 essential tips how to sharpen TIG welding electrodes correctly

Excellent-looking weld seams can be conjured up with TIG welding. It is not only the choice of the right tungsten electrode that has an influence on the appearance and quality of the welding result. HOW the TIG welding electrode is sharpened also has an enormous influence on the weld seam. In this blog we would like to show you how to properly sharpen tungsten electrodes so that this essential welding accessory for the TIG torch can unfold its full effect.

Topics: TIG Torches

Practical tips for welding: 3 reasons for not using water as a coolant for welding

What do you actually use to cool your welding torch? Is water from the regular piping system running through the cooling system of your power source or have you filled in coolant? And do you often have to cope with torch failures? If this is the case, the choice of your coolant could provide information about the reason for the frequent torch failures. In fact, water is often used as a coolant during welding. Why this is not a good idea at all, and why it can even cause torch failures, is explained in this blog.

Practical tips for welding: tungsten electrodes

All about the welding accessories TIG welding electrodes

Last updated on: February 26, 2026

Finely crafted weld seams, clean welded joints, high-quality materials – welcome to the world of TIG welding and tungsten electrodes. Choosing the right tungsten electrode is just as important for TIG welding as the contact tip for MAG welding. The range of TIG welding electrodes on the market is just as colourful as the colour coding that characterizes each individual type of tungsten electrode. In this blog post we would like to give you a helpful overview of the essential tungsten electrodes to make it easier for you to choose if you want to buy them.

Differences in welding fume extraction torches: from the extraction nozzle to the cable assembly

The decision to purchase and use a fume extraction system and a fume extraction torch to capture the health-endangering welding fumes directly at the source is becoming increasingly easier for many people. The awareness of the potentially hazardous gases in welding fumes has cleary spread throughout the industry.

Topics: Fume Extraction

5 reasons for welding with a cobot

It doesn’t have to be a welding robot!

At some point, the time has come and:

- the manual welder reaches the limits of his physical capacity

- the quantities are too large to meet the desired delivery date

- the topic of automation must be discussed

Automation? Aren’t these robot welding cells which usually take up a lot of space and are really expensive? In order to make their purchase profitable, enough parts have to be processed to operate the system at full capacity. In addition, there is the programming of the welding robot, which requires additional knowledge. Is there no interim solution if an industrial welding robot is still a size too big? Yes, there is: cobot welding.

Topics: Robotic Welding

Fume Extraction Kits for Manual, Machine & Robotic Welding Torches

If you are looking to invest in Fume Extraction equipment but you don't want to use manual Fume Extraction torches because they are too heavy, you're using a Machine/Robotic torch and you're concerned about access issues or you're simply on a tight budget - then here are a few external kits that you can use with your existing setup.

RAS Torch Kits

The RAS fume extraction option is an economical and ergonomic alternative to integrated fume extraction torches e.g. RAB GRIP.

Topics: Fume Extraction

Practical tips for welding: How to remove and prevent weld spatter

Anti-spatter spray, anti-spatter liquids, anti-spatter fluid and more

You have to break an egg to make an omelet. Especially with MIG/MAG welding, weld spatter occurs, which can already be heard from afar. With this »crackling and cracking« small metal droplets are created that are hurled from the weld pool or from the hot liquid electrode end to the workpiece surface or land on the weld seam and the torch wear parts. Excessive weld spatter is caused, for example, by an incorrectly set welding current, a non-optimal arc, incorrect polarity or insufficient gas shielding. However weld spatter occurs ... burnt weld spatter has to be removed again. This rework costs time and money. Anyone who welds wants to keep the adhesion of weld spatter as low as possible. And if they do stick, they can easily be removed again. Here we answer the questions that our field staff are asked the most on site.

What costs you will face if you want to buy a fume extraction system

Fume extraction is part of the basic equipment of every welding workplace. There is a wide range of extraction systems on the market, and the requirements are just as individual. From stationary systems that regularly exchange air in a complete production hall to mobile fume extraction with the absorption of welding fume directly at its point of origin, the so-called source extraction, there are many variants. In a previous blog, we went into more detail about the benefits of the extraction at the source. Today we want to focus on the costs that you will face if you want to buy a fume extraction system.

Topics: Fume Extraction

Practical tips for welding: contact tips

What you need to know for the use of power contact tube, contact nozzle, contact tube & Co.

The contact tip – also known as contact nozzle or power contact tube – is the smallest but most important wear part on a MIG/MAG torch, and it makes no difference whether it is a hand-held torch, an automatic torch or a robotic welding torch. The contact tip has a very considerable influence on the quality of the MIG/MAG welding process and the service life or machine availability in the welding process.

Hardly any wear part is subject to deterioration and is as close to the welding process as the contact tip. For this reason, we dedicate our own blog to this relatively small part.Automated welding: How to minimize welding errors

The beam on the workshop floor seems endless. The back hurts already at the mere thought of having to weld in the same position for the next few hours. Take up position, put on, weld off, put down, slide forward. Unfortunately, it is unavoidable that over time the welding seam is not as good as it was at the beginning. Or maybe it can? Automated welding provides a remedy ... for poor weld seam quality of long, repetitive welding tasks, for welding errors, but also for monotonous and painful joints.

Topics: Robotic Welding

Don’t be afraid of automation when welding!

Why cobot welding can be the solution for small and medium-sized companies

Automatically working welding robots as far as the eye can see. The robot arms move sometimes hectically, sometimes silently. There is a hiss, hum, and crackle in the air. You can only recognize a person here and there. Automation clearly dominates. Such a vision is more of a fear image for small and medium-sized companies, because people here seem to be completely in the background, yes, being pushed out of their job. So it seems. A machine like a collaborative robot – a so-called cobot – can support people in their work. The use of cobots in welding can thus become an economical solution for small and medium-sized companies.

Topics: Robotic Welding

BINZEL BASICS: RAB Fume Extraction torch selection, fume nozzles & consumables

Topics: Fume Extraction

5 Tips on how to properly weld aluminum

What really matters when welding aluminum

Frames of bicycles or motorcycles, trailers for trucks, profiles of rail vehicles, materials in space travel – aluminum is THE material when it comes to reducing weight and still achieving stability. In addition, a beautifully welded aluminum seam is a real eye-catcher.

Topics: Aluminum Welding

BINZEL BASICS: MIG torch selection, consumables & torch liners

In this blog we're going to focus on the 3 main topics concerning MIG torches & consumables, these are:

Topics: MIG Guns & Torches, Welding Consumables

How to reduce health burden during welding

With the new xFUME series we are eliminating harmful welding fumes.

In any manufacturing location across the world, air quality and fume control is an increasing concern. While the welder himself bears the most burden in weld fume exposure and long term health risks, it’s not limited to just the welding operator. Across the entire shop floor – from the forklift operator to administrative staff and walk the floor, exposure to weld fumes is a second hand smoke experience. Even if it’s not always visible or noxious, it’s there. There isn’t a welding operation today that in some way doesn’t need fume extraction.

Topics: Fume Extraction, Health & Safety

BINZEL BASICS: What is Plasma Welding?

What is Plasma Welding?

‘Plasma’ is the fourth state of Matter.

Topics: Plasma Welding

BINZEL BASICS: Fume Extraction at Source

Every welding job generates fume or smoke that can be hazardous if inhaled. Whether you're welding mild or stainless steel, there is only one effective solution for maximum health protection....Extraction at source!!

Topics: Fume Extraction

iCAT W Tool Bar Settings: A Quick Guide

This quick guide will show you the correct way to install a water/liquid cooled harness using the iCAT setting bar (part number 980.2153).

Topics: Robotic Welding

iCAT A Tool Bar Settings: A Quick Guide

This quick guide will show you the correct way to install an air/gas cooled harness using the iCAT setting bar (part number 980.2153).

Topics: Robotic Welding

/Blog/ABITIG%20GRIP%20exchangable%20torch%20neck/7W5_ABITIG_GRIP_W_T_Action_01_banner.jpg)

/Blog/Laser_triangulation_in_welding_How_many_lines_does_a_sensor_really_need/Laser_triangulation_how_many_lines_sensor_banner.png)

/Blog/When%20welding%20tolerances%20become%20a%20trip%20to%20hell/Banner_Welding_tolerances_1.webp)

/Blog/Extraction%20torches%20%E2%80%93%20the%20new%20standard%20in%20welding/Banner.jpg)

/Blog/Schweissrauchabsaugung%20W3/Etikett_W3_FES-200_W3_800x300px.jpg)

/Blog/Cobot%20vs.%20Robot/AdobeStock_524333381_automation_800_300.jpg)

/Blog/Herausforderungen%20beim%20thermischen%20Schwei%C3%9Fen%20von%20Aluminium/1_AS_116914022_Karosserie_Alu_800x300.jpg)

/Blog/Warum%20beim%20WIG-Schwei%C3%9Fen%20Absaugung%20ein%20Muss%20ist/Teaser_WIG_Schweissen_800x300px_V1.jpg)

/Blog/Calculating_gas_saving/Gas_saving_notebook_banner.jpg)

/Blog/Gas%20saving/Header_Gas_Sparen_800x300px.jpg)

/Blog/Beizen/Lkw_Edelstahl_AS_357297701_800x300px_Teaser.jpg)

/Blog/Stillstandzeiten/3/Teaser_Blog_3_800x300.jpg)

/Blog/Stillstandzeiten/2/Teaser_Blog2_EN.jpg)

/Blog/Stillstandzeiten/1/Teaserbild_Blog_Stillstand_800x300px.jpg)

/Blog/Gasmanagement/AdobeStock_24208825_Banner.jpg)

/Blog/Welche%20Gasd%C3%BCsen%20f%C3%BCr%20MAG-Schwei%C3%9Fen/Gasduesen_MIG_MAG_banner.jpg)

/Blog/Ist%20Alu-Schwei%C3%9Fen%20giftig/Welding_Aluminum_800x300px.png)

/Blog/Schweissrauchabsaugung%20FAQs/Fume_Extraction_Torch_in_Action.png)

/Blog/Fume%20extraction%20for%20robotic%20welding%20%E2%80%93%20nice-to-have%20or%20must-have/fume_production.jpg)

/Blog/Cause%20of%20weld%20spatter%20-%20GMAW%20welding%20and%20electric%20arc/Lichtbogen.jpg)

/Blog/Schwei%C3%9Ftrennmittel%20-%20unschlagbar,%20unbrennbar/Welding_Chemicals_Blog_Banner_AdobeStock_87469315.jpg)

/Blog/Die%205%20h%C3%A4ufigsten%20Fehler%20beim%20Einsatz%20eines%20Rauchgas-Absaugbrenners/Fume_AdobeStock_122332205.jpg)

/Blog/Vorteile%20und%20Unterschiede%20nicht%20brennbarer%20Schwei%C3%9Ftrennmittel/Super_Pistolenspray_NF_Vergleich_Flamme_800x300.jpg)

/Blog/Aluminium%20welding%20with%20a%20Cobot/Cobot_Aluminium_Welding_2.jpg)

/Blog/Automated_TIG_Welding/ABITIG_MT_500W_KDZ_CAT2_Fanuc_LB_0064_oCAT2.jpg)

/Blog/Gefahren%20beim%20Schweissen%20-%20Warum%20der%20Schweissbrenner%20nicht%20zur%20Last%20werden%20sollte/Schweisser-Weinberger_MB_EVO_PRO_01_800x300.jpg)

/Blog/Green_Factory/AdobeStock_297584270_Green_Factory_banner.jpg)

/Blog/Praxis_Tipps_Schweissen_Richtig_schweissen_mit_Absaugbrennern/RAB_GRIP_HE_Action_800x300.jpg)

/Blog/Robotics/CAT3_PRO_TR_Action_800x300px.jpg)

/Blog/What_you_should_consider_with_welding_fume_filters/2025_Banner_xFUME_PRIME_details_0131-1.jpeg)

/Blog/EWR/EWR_2_banner.jpg)

/Blog/Tungsten%20electrodes/Wolframelektroden_Anschleifen_ULTIMA_TIG_D_banner.jpg)

/Blog/BTC-20_NF_Action_banner.jpg)

/Blog/Tungsten%20electrodes/Wolframelektroden_Banner.jpg)

/Demo%20Request%20Fume%20Extraction%20Torches/RAB_GRIP_501D_HE_Action_LP_Demo.png)

/Demo%20Request%20iBOTone/iBOTone_cpl_color_1200x450_banner.jpeg)

/Blog/Praxis_Tipps_Schwei%C3%9Fchemie/ABIBLUE_Action_Header_.jpg)

/Blog/Was%20an%20Kosten%20auf%20Sie%20zukommt,%20wenn%20Sie%20eine%20Absauganlage%20kaufen%20wollen/Calculator_Budget_Stockphoto.jpg)

/Blog/Praxis_Tipps_Schwei%C3%9Fen_Stromd%C3%BCsen/Header_Stromduesen_800x300px.jpg)

/Blog/Automatisiertes%20Schwei%C3%9Fen%20-%20So%20minimieren%20Sie%20Schwei%C3%9Ffehler/SpoolWeldingRobot-NOVARC-weld-seam-control-on-screen_blog_banner.jpg)

/Demo%20Request%20iBOTone/iBOTone_Action_with_welder_1200x600_banner.jpeg)

/Blog%20Pictures/RAB_GRIP_bw.jpg)

/Blog/Aluminiumwelding_weldingseam_featured_image.jpg)

/Blog%20Pictures/Nissan_iCAT_Tool_Bar_B.jpg)

/Blog%20Pictures/Nissan_iCAT_A_Tool_Bar_2.jpg)