Have you ever passed the mandatory vehicle inspection even though the emissions were not right? Have you ever lit a cigarette in a restaurant in Germany in the last 15 years and waited to see the reactions? So why should you continue to weld without a fume extraction torch knowing how harmful welding fumes are to your health?

Extraction torches – the new standard in welding?

Topics: Fume Extraction

Welding fume extraction W3 – What you should know about it

Welding fume extraction is an important aspect in industrial manufacturing to control air quality and protect the health of employees. Welding fume class W3 is of particular importance. What is meant by this and who needs a welding fume extraction system with W3 certification?

Topics: Fume Extraction

Why extraction is a must in TIG welding

TIG welding is considered to be a very clean welding process, as little or no welding fumes usually rise during work. But appearances are deceptive. Even though there are not much welding fumes generated, it is important not to underestimate the dangers of TIG welding. Because other factors also play a role and they make TIG extraction a good solution.

Topics: Fume Extraction, Health & Safety, TIG

Is aluminum welding toxic?

When welding aluminum, as with all other weldable metals and metal alloys, emissions arise in the form of combustion and evaporation residues.

Which protective measures are suitable here and is aluminum welding toxic?

Topics: Fume Extraction

The 11 most frequently asked questions about fume extraction

When it comes to welding fume extraction, a couple of questions are frequently asked. Often it is about the performance, weight or handling of fume extraction torches, but also the service life of welding fume filters in extraction devices or the correct volume flow control are recurring topics.

Since welding fumes are toxic and the extraction of welding fumes should be mandatory to protect employees, we answer the most frequently asked questions about welding fume extraction and clear up common prejudices and concerns so that you can find the perfect solution for you and your welders.

Topics: Fume Extraction

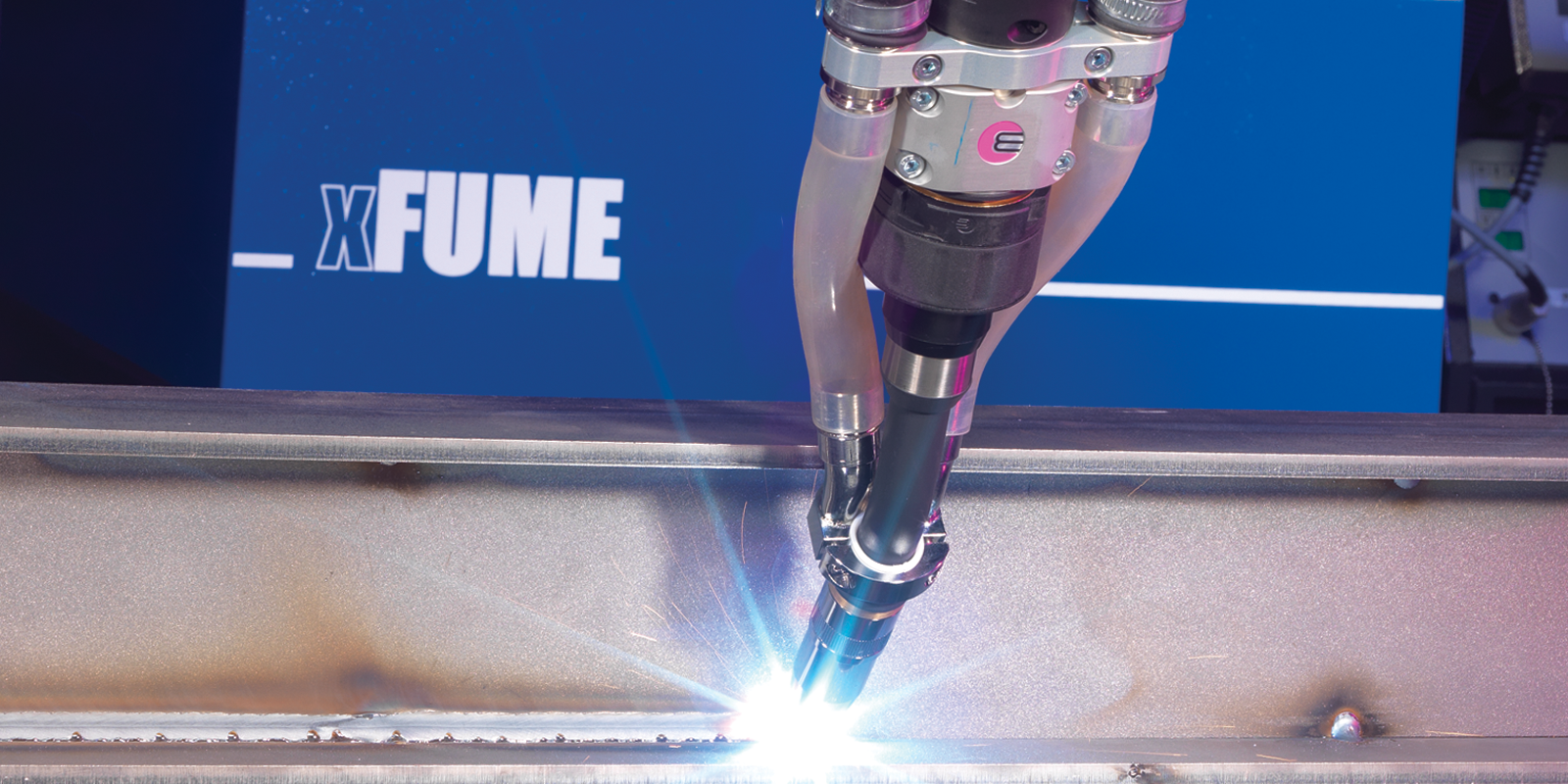

Fume extraction for robotic welding – nice-to-have or must-have?

The fact that the welder is close to the welding process and would therefore be completely exposed to the dangerous gases in the welding fumes without a fume extraction system is no surprise. But how is the situation when using a robot for welding? Do similar precautions need to be implemented as with manual welding? Just as with manual welding, the dangers of welding fumes should not be underestimated.

Topics: Robotic Welding, Fume Extraction

5 mistakes to avoid with a fume extraction torch

Extracting harmful welding fumes should be standard in every manufacturing company for health reasons. Many rely on large extraction systems for extraction, which completely exchange all of the hall air within a very short time. More efficient and far cheaper than such large air filtration systems are extraction devices where appropriate fume extraction torches can be connected for source capture. With the fume extraction torches from ABICOR BINZEL, fume extraction is easy.

Topics: Fume Extraction

Welding correctly with fume extraction torches: 3 practical tips

When welding metals, there are a number of emissions which, on the one hand, cause the legally prescribed MAK values (“maximale Arbeitsplatz-Konzentration”: maximum workplace concentration) to rise above the permissible threshold value and, due to toxic and / or disease-causing ingredients, represent a health risk for the personnel in the processing area. This fact obliges companies in the welding industry in particular to ensure effective air filtering and ventilation in the areas concerned. Because not only the welder himself is affected by the harmful emissions, but also the rest of the staff in the production hall, who are exposed to the welding fumes.

In addition to a large number of stationary fume extraction systems, the torch-integrated fume extraction (fume extraction torches) is one of the most effective and mobile methods that can be used. Welding with fume extraction torches is definitely a challenge when it comes to the handling.

So how can you weld correctly with fume extraction torches? What do you need to pay attention to?

Topics: Fume Extraction, MIG Guns & Torches

What you should consider with welding fume filters

Purchasing a fume extraction unit is the first step in the right direction. To protect the welder and other endangered persons from the dangers of welding fumes for as long as possible, there are a few things to consider, especially when it comes to the fume filters. The fume filter ensures that the hazardous gases in the welding fumes are filtered out and that the working environment is safe for everyone. How exactly does that work?

Topics: Fume Extraction

Differences in welding fume extraction torches: from the extraction nozzle to the cable assembly

The decision to purchase and use a fume extraction system and a fume extraction torch to capture the health-endangering welding fumes directly at the source is becoming increasingly easier for many people. The awareness of the potentially hazardous gases in welding fumes has cleary spread throughout the industry.

Topics: Fume Extraction

Fume Extraction Kits for Manual, Machine & Robotic Welding Torches

If you are looking to invest in Fume Extraction equipment but you don't want to use manual Fume Extraction torches because they are too heavy, you're using a Machine/Robotic torch and you're concerned about access issues or you're simply on a tight budget - then here are a few external kits that you can use with your existing setup.

RAS Torch Kits

The RAS fume extraction option is an economical and ergonomic alternative to integrated fume extraction torches e.g. RAB GRIP.

Topics: Fume Extraction

What costs you will face if you want to buy a fume extraction system

Fume extraction is part of the basic equipment of every welding workplace. There is a wide range of extraction systems on the market, and the requirements are just as individual. From stationary systems that regularly exchange air in a complete production hall to mobile fume extraction with the absorption of welding fume directly at its point of origin, the so-called source extraction, there are many variants. In a previous blog, we went into more detail about the benefits of the extraction at the source. Today we want to focus on the costs that you will face if you want to buy a fume extraction system.

Topics: Fume Extraction

BINZEL BASICS: RAB Fume Extraction torch selection, fume nozzles & consumables

Topics: Fume Extraction

How to reduce health burden during welding

With the new xFUME series we are eliminating harmful welding fumes.

In any manufacturing location across the world, air quality and fume control is an increasing concern. While the welder himself bears the most burden in weld fume exposure and long term health risks, it’s not limited to just the welding operator. Across the entire shop floor – from the forklift operator to administrative staff and walk the floor, exposure to weld fumes is a second hand smoke experience. Even if it’s not always visible or noxious, it’s there. There isn’t a welding operation today that in some way doesn’t need fume extraction.

Topics: Fume Extraction, Health & Safety

BINZEL BASICS: Fume Extraction at Source

Every welding job generates fume or smoke that can be hazardous if inhaled. Whether you're welding mild or stainless steel, there is only one effective solution for maximum health protection....Extraction at source!!

Topics: Fume Extraction

/Blog/Extraction%20torches%20%E2%80%93%20the%20new%20standard%20in%20welding/Banner.jpg)

/Blog/Schweissrauchabsaugung%20W3/Etikett_W3_FES-200_W3_800x300px.jpg)

/Blog/Warum%20beim%20WIG-Schwei%C3%9Fen%20Absaugung%20ein%20Muss%20ist/Teaser_WIG_Schweissen_800x300px_V1.jpg)

/Blog/Ist%20Alu-Schwei%C3%9Fen%20giftig/Welding_Aluminum_800x300px.png)

/Blog/Schweissrauchabsaugung%20FAQs/Fume_Extraction_Torch_in_Action.png)

/Blog/Fume%20extraction%20for%20robotic%20welding%20%E2%80%93%20nice-to-have%20or%20must-have/fume_production.jpg)

/Blog/Die%205%20h%C3%A4ufigsten%20Fehler%20beim%20Einsatz%20eines%20Rauchgas-Absaugbrenners/Fume_AdobeStock_122332205.jpg)

/Blog/Praxis_Tipps_Schweissen_Richtig_schweissen_mit_Absaugbrennern/RAB_GRIP_HE_Action_800x300.jpg)

/Blog/What_you_should_consider_with_welding_fume_filters/2025_Banner_xFUME_PRIME_details_0131-1.jpeg)

/Demo%20Request%20Fume%20Extraction%20Torches/RAB_GRIP_501D_HE_Action_LP_Demo.png)

/Blog/Was%20an%20Kosten%20auf%20Sie%20zukommt,%20wenn%20Sie%20eine%20Absauganlage%20kaufen%20wollen/Calculator_Budget_Stockphoto.jpg)

/Blog%20Pictures/RAB_GRIP_bw.jpg)