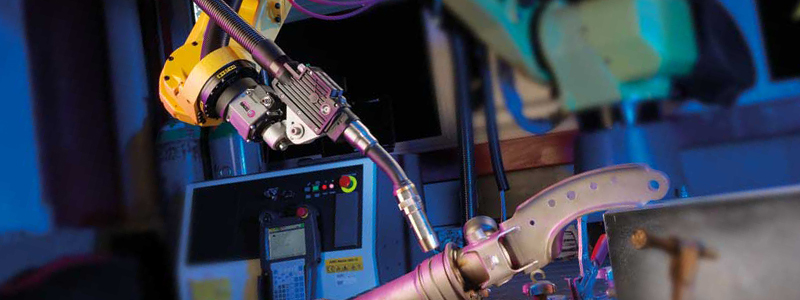

Wire feeding is a critical part to your automated welding process. Without functioning wire, this multi-layered, complex process would not deliver optimal performance. This could lead to complete failure of your process. Challenges can arise due to wire feed speed, wire feed distance, and friction within the system causing a host of problems throughout your process. As you continue to understand your robotic welding cell, it is important to evaluate your wire feed practices.

Keys to Wire Feeding In Automated Robotic Welding Applications

Topics: Robotic Welding, Automation

Automated Welding: Getting Started and Next Steps

Making the switch from manual to automated welding can be an on-going pros and cons discussion for your facility. Giving control to a robot may be a daunting task for anyone new to this application process, but is a necessary step in getting the most out of your operation. Decreasing production times and taking the load off of your welders may be all you need to go full automation.

Let’s take a look at what it would take for your facility to incorporate automated technology and what you should be taking note of throughout this integration process.

Topics: Robotic Welding, Automation

Troubleshooting Robotic Welding Arc Faults

Robotic welding is all about time and minimizing the loss of it. Everything from porosity, microarcing, and spattering contributes to an inefficient welding process that requires troubleshooting and problem solving.

Topics: Robotic Welding

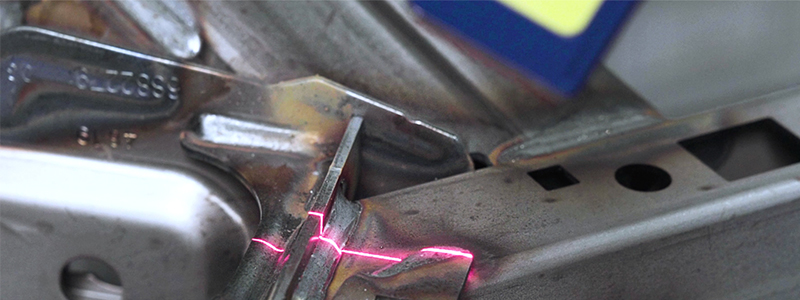

Comparing Weld Inspection Methods

No matter how good your welding process is, weld defects are inevitable. Inspection ensures those defects are caught and fixed before your product goes out the door. Leaving this unaddressed can lead to customer issues, premature product failure, and a lot of other avoidable mistakes. In my experience, I have seen a number of issues impact welding. One of my most memorable experiences was during my time at Tower. We would always run into inconsistency in parts which caused a frenzy in figuring out the reasoning why. We'd argue with our internal and external stamping supplies, have holes and trimmed edges that would move or change, and spend countless hours on the robot cells touching up welds here and there. This lead to many different quality issues and wasted time chasing down and troubleshooting these inconsistencies.

Topics: Robotic Welding, Automation, Weld Inspection

What Changes When Implementing Robotic Fume Extraction In Your Operation?

Are you looking to continue advancing your welding process? You've completed the first step by adding robots to your operation, but now you're looking to improve safety among your team. Step two is setting up a robotic fume extraction system in your plant to improve air quality. The xFUME® ROBO by ABICOR BINZEL USA and CA is the most effective and economical way to control welding smoke emissions with fume source capture.

Topics: Robotic Welding, Fume Extraction

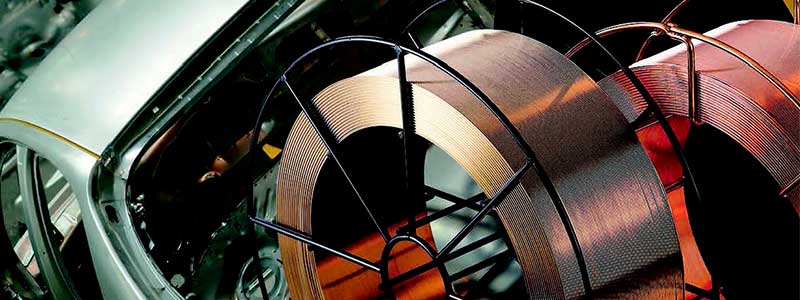

Explaining Weld Wire Cast for Robotic Welding

There are two physical elements of weld wire to be aware of in a robotic welding application. The first is the cast, which is the natural curvature of the wire. The second is the helix, which is the natural winding geometry of the wire's radial shape.

Topics: Robotic Welding, Welding Consumables

New Product Releases ABICOR BINZEL USA: xFUME® Fume Extraction Solutions

ABICOR BINZEL USA is now offering full turn-key solutions to fume extraction welding in both automated, robotic applications and manual applications.

Topics: Robotic Welding, Fume Extraction, MIG Guns & Torches, Company News, Products, New Product Release

How to Limit Micro-Arcing in Robotic Welding

Micro-arcing in a welding process are small arcs, usually not visible, that happen within the contact tip or wire liner. Instead of making a positive contact all the way through the tip, or at least always on the tip at some point, your wire is making inconsistent contact to the contact tip. This compromises current transfer and causes the wire to micro-arc inside the contact tip.

Topics: Robotic Welding

Understanding Porosity in Robotic Welding

Porosity is the bane of existence in robotic welding.

It happens. You don’t know where it comes from all the time, or how it’s happening, and you spend days or even weeks troubleshooting to figure it out.

We’ve all been there.

Topics: Robotic Welding

Solving Welding Burnbacks in Robotic Applications

A burnback in welding is when your wire burns back and sticks itself to your contact tip. There are several reasons this can happen. The most primary causes of burnbacks in a robotic application include:

Topics: Robotic Welding

-2.png)

/Blog%20Photos/How%20to%20Limit%20Micro%20Arcing%20in%20Robotic%20Welding/800x300_Robo_WH.jpg)