The future of manufacturing is here, and it's being shaped by collaborative robots, specifically cobot welders. These machines are revolutionizing welding solutions, making welding faster, easier, and more efficient.

If you're thinking of investing, you're probably wondering: what's the real cost of bringing these advanced welding systems on board? Let's dive into the factors that drive the price and explore what you can expect to invest.

More

Topics:

Robotic Welding,

Automation

Imagine this: Your business faces a flood of activity. Orders pile up. Welding bottlenecks are killing your production. Each weld looks different from the last. Sound familiar?

If so, cobot and robot welding might be what you need. Both boost speed, quality, and lead to increased productivity. The question is, which one fits your shop?

This article will give you a close look. We'll break down each technology, so you can make the best choice for you and your shop.

More

Topics:

Robotic Welding,

Automation

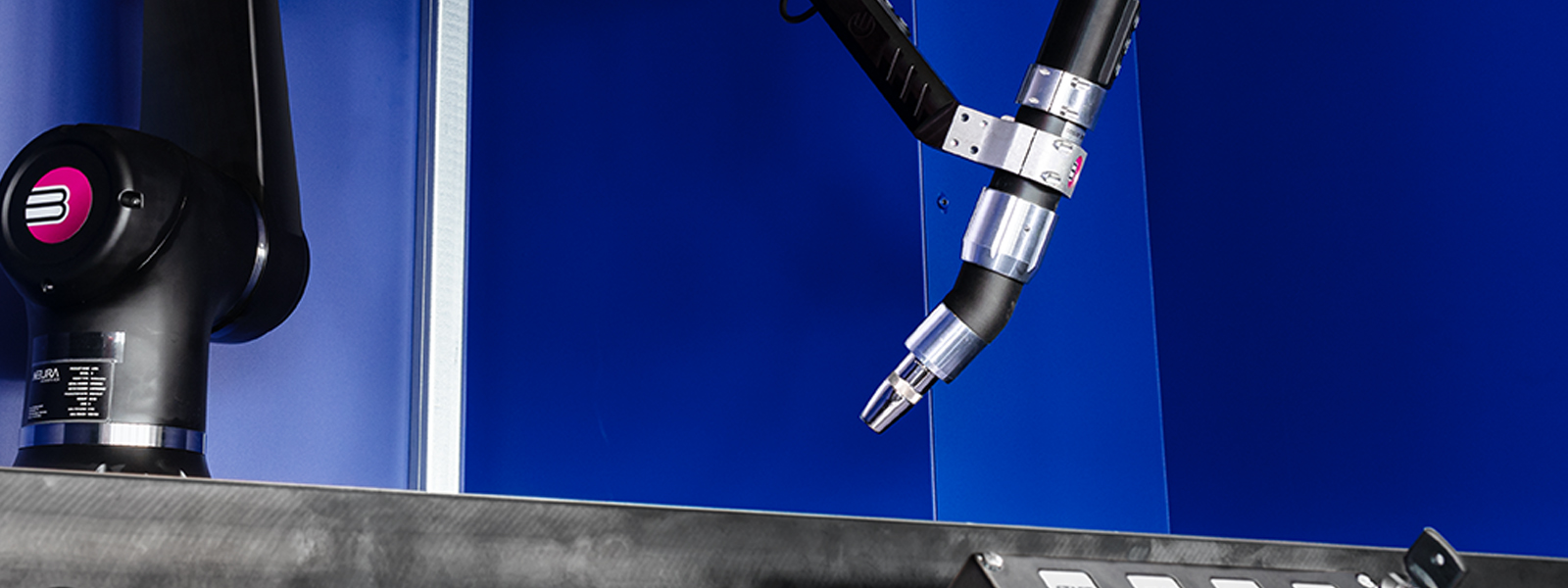

Collaborative robots - or cobots - are increasingly changing the manufacturing landscape. By automating tasks, cobots have helped manufacturers streamline their operations and boost productivity. Specifically for welding, cobots have brought a level of precision and flexibility that's hard to match.

Despite the recent spark in interest, there are still some misconceptions floating around that might be holding you back from investing. So, lets go over five common misconceptions about cobot welders and try to debunk them

More

Topics:

Robotic Welding,

Automation

Welding can be a challenge, especially when it comes to meeting position tolerances. Poorly prefabricated components, clamping issues, and heat distortion can all throw a wrench in the works. Sound familiar?

More

Topics:

Robotic Welding,

Seam Tracking

In today's fast-paced environment, companies are constantly on the lookout for innovative solutions that drive productivity while also minimizing costs. In the world of welding, collaborative robots (cobots) have emerged as a promising solution, gaining widespread traction. Businesses around the globe are discovering that cobots offer a versatile and cost-effective way to boost efficiency. In today's blog, we're going over some of the ways that cobots can increase your ROI and maximize your savings.

More

Topics:

Robotic Welding,

Automation

There are countless robotic welding cell setups tailored to various jobs, and it's rare to find two that are exactly alike. This diversity stems from the wide range of welding automation needs for different parts and products.

Despite their differences, most robotic welding cells share a common trait: they could benefit from performance improvements. These enhancements can range from minor adjustments that simplify programming and maintenance or extend the lifespan of parts, to more significant changes like adding peripheral equipment to reduce long-term costs and increase uptime.

Let's go over six practical ways to improve the efficiency of your robotic welding cell.

More

Topics:

Robotic Welding,

Automation

Welding with collaborative robots or cobots, introduces unique safety challenges that require careful planning and proactive measures. Implementing key safety practices can protect workers and maintain a safe work environment.

More

Topics:

Robotic Welding,

Automation

In recent years, the manufacturing industry has faced a significant challenge – a shortage of skilled welders. As businesses strive to maintain and improve their welding processes, many are turning to innovative solutions, and one technology is standing out: collaborative robots, or cobots. Let's dive into how cobots, are addressing the shortage of welders and bringing significant value to businesses through the welding process.

More

Topics:

Robotic Welding,

Automation

In the fast-paced world of welding, staying ahead of market demands is crucial. The team at ABICOR BINZEL USA is committed to continuously expanding their range of top-notch welding fume extraction solutions. The latest addition to their impressive lineup is a robotic welding torch xFUME® ABIROB® AF500, which integrates seamlessly into your robotic welding cells.

More

Topics:

Robotic Welding,

Fume Extraction,

MIG Guns & Torches,

Company News,

Products,

New Product Release

Maximize safety and efficiency in your welding shop with ABICOR BINZEL's xFUME® line - the ultimate solution for fume extraction.

More

Topics:

Robotic Welding,

Fume Extraction,

MIG Guns & Torches,

Company News,

Products,

New Product Release

.png)

-2.png)

-2.png)