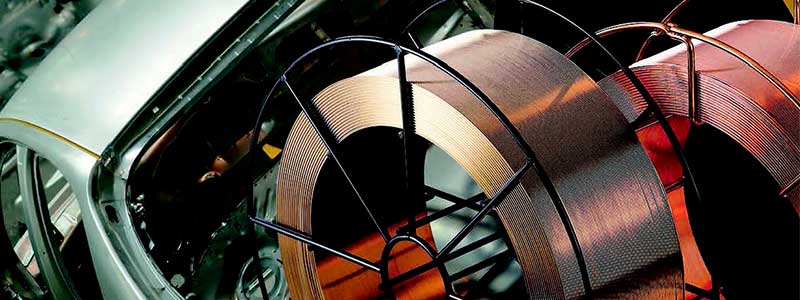

When considering the needs of your robotic welding set up, there are far more components to worry about than just the torch. Cables are an often-overlooked part of your setup, but can make a world of difference in efficiency and productivity.

Your cable decision stems from a full understanding of your robotic welding process. In this blog, we will break down the necessary steps you should take as you consider different robotic MIG torch cables.

.png)

/Blog%20Photos/How%20to%20Limit%20Micro%20Arcing%20in%20Robotic%20Welding/800x300_Robo_WH.jpg)