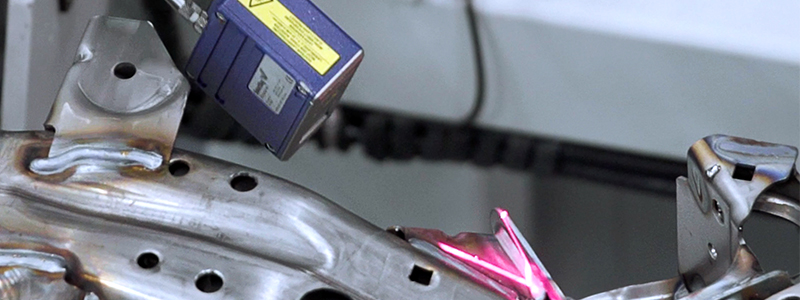

Weld inspection is a topic discussed time and time again, as many debate what the best process is and why it will provide the best overall result. This is where the collaboration between SmartRay and ABICOR BINZEL comes into play.

Automated Weld Inspection with BINZEL and SmartRay

Topics: Automation, Weld Inspection

Why You Should Integrate Automated Weld Inspection Into Your Process

When it comes to weld inspection, this portion of your weld process is among the most crucial. With a majority of facilities using visual weld inspection methods to pass welds as good or bad, you encounter a major inconsistency issue and run the risk of missing bad welds.

Topics: Weld Inspection

Automotive Weld Inspection: Technology Every Manufacturer Should Know

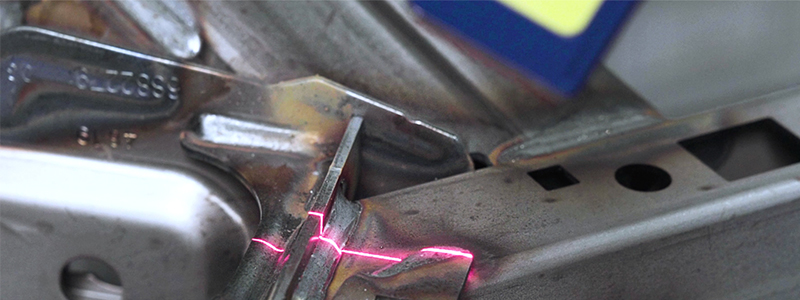

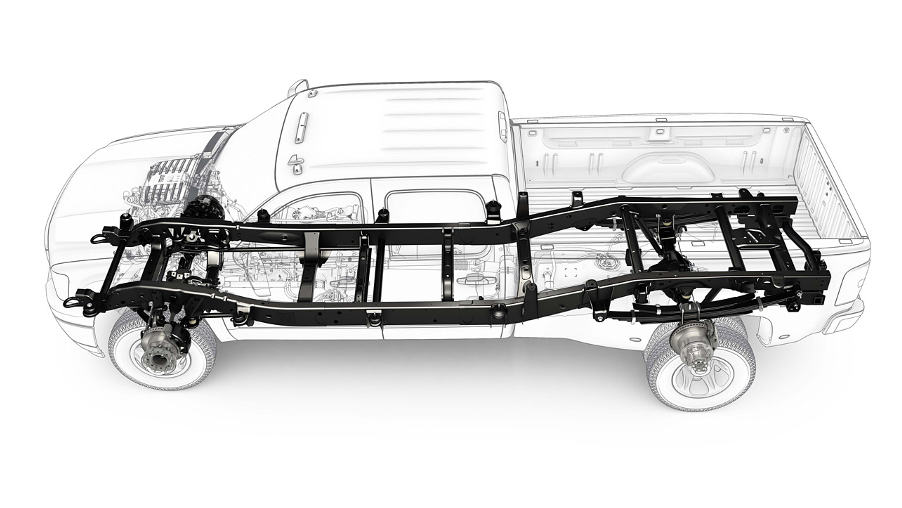

When looking at automotive weld inspections and the applications they can be used in, the realm of possibilities are wide open. From MIG and MAG to laser brazing and welding, all of these applications (1) require inspection to ensure they meet process specifications and (2) are often suitable for automation. This is becoming more and more important as companies are realizing that when you have welds on critical automotive parts, especially very expensive parts, you cannot afford to take a nonchalant approach to executing this critical task.

Topics: Weld Inspection

What is 3D Inline Weld Inspection? Does My Business Need It?

One of the first questions that we get asked in regards to 3D weld inspection is...

- How does it work?

- What are the basic principles?

- How does it understand the dynamics of what we're looking for and not looking for?

In this blog, we will discuss the characteristics of 3D weld inspection and provide the necessary information about this process to determine whether or not these systems fit your operation's needs.

Topics: Automation, Weld Inspection, SmartRay

Comparing Weld Inspection Methods

No matter how good your welding process is, weld defects are inevitable. Inspection ensures those defects are caught and fixed before your product goes out the door. Leaving this unaddressed can lead to customer issues, premature product failure, and a lot of other avoidable mistakes. In my experience, I have seen a number of issues impact welding. One of my most memorable experiences was during my time at Tower. We would always run into inconsistency in parts which caused a frenzy in figuring out the reasoning why. We'd argue with our internal and external stamping supplies, have holes and trimmed edges that would move or change, and spend countless hours on the robot cells touching up welds here and there. This lead to many different quality issues and wasted time chasing down and troubleshooting these inconsistencies.

Topics: Robotic Welding, Automation, Weld Inspection