As technology advances, your workplace must adapt to keep up with the need. That period of adapting will look different for everyone, as some operations needs are on a much smaller scale than others. For those in larger manufacturing plants, the push to automate has become a more prevalent move. Productivity is the name of the game and to keep up, operations must be able to repeat their tasks quickly and efficiently.

Robots & Robotic Welding Torches | ABB Robotics x ABICOR BINZEL

Topics: Robotic Welding, Automation

Seam Tracking and Welding Peripherals: ABICOR BINZEL x Yaskawa Motoman

With the current state of the welding industry as it sits now, we are seeing a lot of manufacturers moving away from manual to create a more automated process. With this comes a host of new welding equipment that can benefit your process, from improving repeatability and traceability, to increasing productivity and general performance.

Topics: Robotic Welding, Automation

Seam Tracking and Automation Solutions | BINZEL x ABB Robotics

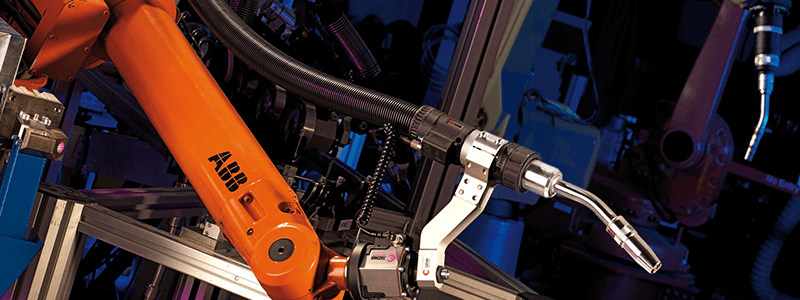

When it comes to providing value through collaboration, the duo of ABB Robotics and ABICOR BINZEL does just that by innovating and integrating automation solutions for you.

With a top-of-the-line ABB robot, with welding torches and peripherals added to the table from BINZEL, customers can be sure they are receiving the highest-quality welding equipment available.

Topics: Robotic Welding, Automation

Robotic Welding with ABICOR BINZEL & Yaskawa Motoman

ABICOR BINZEL manufactures high quality MIG welding products and peripheral equipment, from torch cleaning stations to torch exchange stations. In addition, BINZEL has a complete line of sensors, from laser seam tracking to automated weld inspection.

Topics: Robotic Welding, Automation

Automation in Pipe Welding: ABICOR BINZEL x Novarc Technologies

Automation is one of the leading trends in the pipe welding industry today because pipe fabrication shops are looking for ways to increase productivity and quality, while trying to combat the shortage of qualified welders. ABICOR BINZEL has partnered with Novarc Technologies to resolve this problem and provide a meaningful solution that improves this production process. BINZEL serves as Novarc's global sales and service partner for the Spool Welding Robot (SWR), continuing our efforts to provide exceptional product and service quality. This partnership is delivering massive productivity and quality increases, making our customers more competitive in the markets they serve.

Topics: Pipe Welding, Robotic Welding, Automation

Weld Process Monitoring for Industry 4.0

Industry 4.0 is all about the ongoing transition into an even smarter, automated manufacturing world, using new developments in technology to get us there. Through the use of intelligent, automated technology, we are able to communicate more efficiently, collect data with advanced traceability, and create human-like interactions between machines and computers.

Topics: Robotic Welding, Laser Welding, Automation

Robotic Air-Cooled Welding Torches: Problems and Solutions

Robotic MIG welding requires a choice between which type of welding torch to use in your operation. The option between water-cooled and air-cooled torches requires weighing the pros and cons because making your decision. Each torch has its benefits and downfalls that can alter the productivity of your operation.

Topics: Robotic Welding

Robotic MIG Torch Cables: Best Practices

When considering the needs of your robotic welding set up, there are far more components to worry about than just the torch. Cables are an often-overlooked part of your setup, but can make a world of difference in efficiency and productivity.

Your cable decision stems from a full understanding of your robotic welding process. In this blog, we will break down the necessary steps you should take as you consider different robotic MIG torch cables.

Topics: Robotic Welding

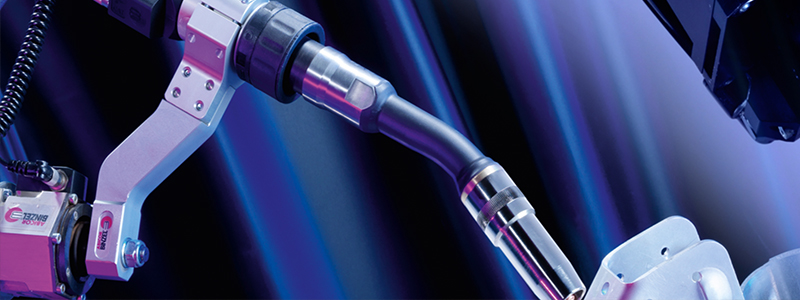

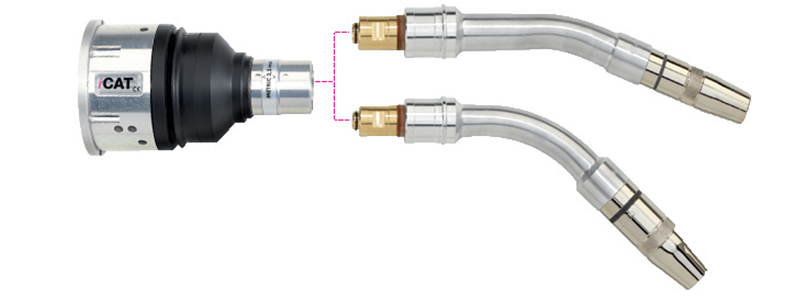

Robotic Welding Torch Swanneck Breakdown: Build, Design, and Construction

When it comes to your robotic welding torch, the swanneck (sometimes known as the gooseneck or torch neck) is one of your most critical parts. What is a swanneck? It is the front end or “working end” of a robotic welding torch, where the contact tip and gas nozzle are mounted to deliver the electrical current, filler wire, and shielding gas into the weld joint.

Topics: Robotic Welding

Robotic Water-Cooled Welding Torches - Problems and Solutions

Robotic MIG welding requires a choice when it comes to which welding torch to use for your operation. Your facility will need to weigh the options for using a water-cooled or air-cooled welding torch based on research you have done regarding both. Each torch type has its benefits and downfalls that can alter productivity. Is your torch providing the amperage ratings and duty cycle you’re looking for while staying within your budget? These factors are essential to consider, along with understanding common problems you will run into with your new equipment.

Topics: Robotic Welding, MIG Guns & Torches

/Landing%20Pages/Partners%20and%20Relationships%20Page/800x300_ABB_01.jpg)

/Landing%20Pages/Partners%20and%20Relationships%20Page/800x300_Yaskawa_01.jpg)

/Blog%20Photos/Novarc%20x%20Binzel/SWR.jpg)

.png)