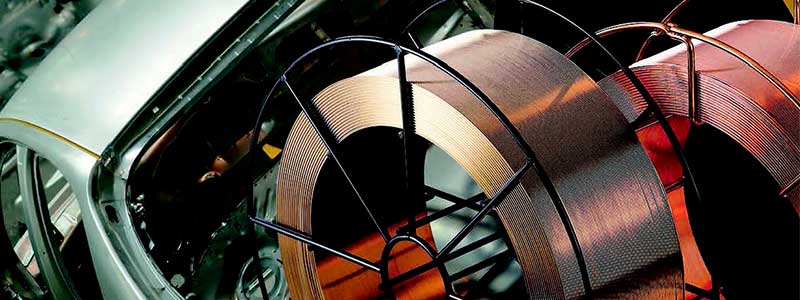

There are two physical elements of weld wire to be aware of in a robotic welding application. The first is the cast, which is the natural curvature of the wire. The second is the helix, which is the natural winding geometry of the wire's radial shape.

Explaining Weld Wire Cast for Robotic Welding

Topics: Robotic Welding, Welding Consumables

How to Test Welding Contact Tips

When evaluating the cost of your welding operation, it is important to consider the low-cost items that stack up over time; like your consumables, and more specifically, your contact tips.

Topics: Welding Consumables

MIG Gun Liner Types & Best Practices

In today’s environment it is absolutely critical to minimize downtime and operate in the most efficient manner. Reasons for downtime are many and varied, particularly in the welding fabrication field. Grounding problems, gas leaks, contaminated material, machinery malfunction and worn components represent a few of the many issues confronted. In MIG welding, one of the most frustrating is wire feed problems and MIG gun liner issues in general.

Topics: MIG Guns & Torches, Welding Consumables

Understanding MIG Welding Nozzles

With your MIG gun you have a variety of welding nozzle designs to choose from, and sometimes the decision on which to choose is not always clear.

Topics: Welding Consumables

Understanding Contact Tips for MIG Welding

Welding contact tips are highly misunderstood components in a MIG gun setup. Choosing the correct contact tip for your welding application and understanding how to keep it performing at its best are just as critical as anything else needed to produce a quality weld.

Topics: Welding Consumables

MIG Gun Welding Diffusers: Copper vs. Brass

We often see different materials used for welding torches and their consumables. Mostly you can see Brass and Copper or Copper alloy - depending on the needs. Since there are various Copper alloys, we focus on the Copper Alloy: CuCr1Zr. Remember also that Brass, which is known as an alloy from Copper and Zinc, has many variations, as well. We will work with an example here.

Topics: Welding Consumables

3 Problems with Contact Tips and How to Solve Them

Usually when I'm meeting with a Foreman or Production Manager and get a chance to talk first hand to his or her welders, one of the most common topics that come up is their contact tips. The problem: they have to change them too much. This kills productivity for the shop, takes a big bite out of cost, and generally just creates a less efficient atmosphere for the welder to work in.

Topics: Welding Consumables

.png)

.png)