At ABICOR BINZEL USA, we understand that downtime in your manufacturing process can be costly. That's why we are dedicated to providing comprehensive welding repair services that keep your operations running smoothly. Imagine being able to redeploy your team from tedious repair tasks to more critical areas in your facility, boosting productivity and saving costs. By entrusting your welding torches to ABICOR BINZEL USA, you can achieve just that.

ABICOR BINZEL USA: Your Partner in Welding Service and Repair On-Demand

Topics: Aluminum Welding, MIG Guns & Torches, Company News

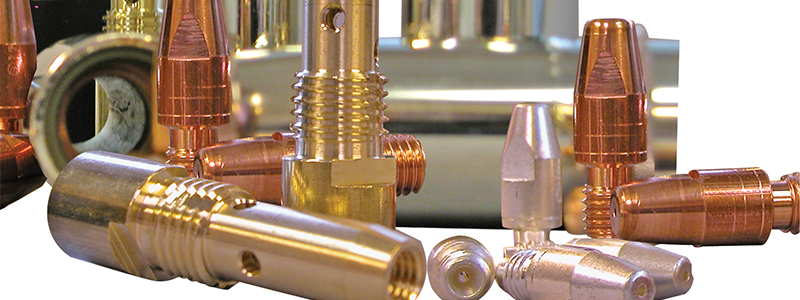

The Best Consumables For Aluminum Welding

Aluminum welding has become one of the most popular forms of welding in the industry today, with a special interest being in the automotive sector. Understanding how to successfully weld aluminum becomes the tricky part, as it is not the easiest material to work with. The process as a whole has its challenges, from preparation and correct welding techniques to specific equipment that should be used to help your operation run smoothly.

For this reason, aluminum requires specific consumables to ensure your welding jobs are completed with minimal issues and ease. In this blog, we will break down the necessary consumables needed to properly weld aluminum.

Topics: Aluminum Welding

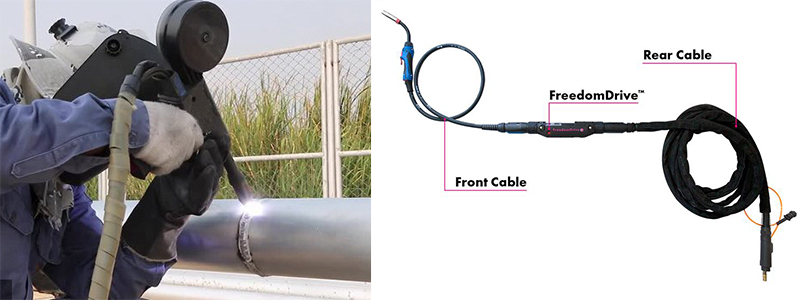

The Problems With Push-Pull & Spool Guns That FreedomDrive™ Solves

Those experienced in push-pull welding understand the challenges that can arise when using this type of equipment. When it comes to ensuring consistent and problem-free wire feeding, you can frequently experience issues or limitations - some being tied specifically to your push-pull welding gun.

Topics: Aluminum Welding, MIG Guns & Torches

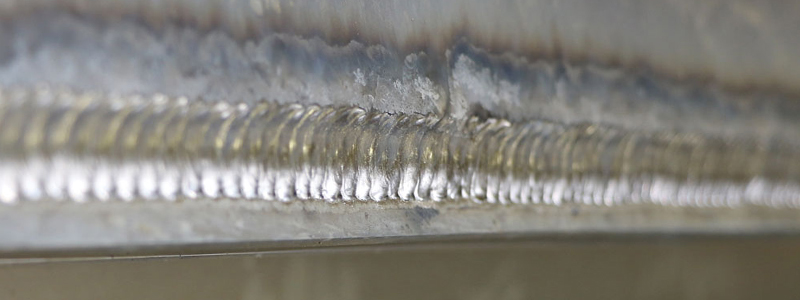

Common Problems in Aluminum Welding and How to Resolve These Issues

As aluminum welding remains a rising force in the industry, continuing to test and understand the problems that come along with it is essential. With all the advantages that aluminum brings, there are also some aspects of this material that makes it tricky to weld with. For starters, aluminum is very soft, leading to many of the issues we will discuss.

Topics: Aluminum Welding

Do I Need A Spool Gun to Weld Aluminum?

There is no question that aluminum has special characteristics that require it be welded different than other metals. Aluminum is a very soft metal, with a high melting point that requires high voltages. Distorting aluminum is easy and can happen pretty quickly, as the wire will start oxidizing almost immediately, leading to a host of issues. Spool guns were designed to help feed difficult wire in an effort to avoid messy welding by placing the feeder right on the gun. Reliable wire feeding is among the most important parts of welding.

Topics: Aluminum Welding

3 Things You Need to Successfully Weld with Aluminum

If you know welding, then you know, one of the more complicated types of materials to work with is aluminum. Preparation, wire feeding, and shielding gas play a big role in successfully welding with aluminum.

Topics: Aluminum Welding

The Rise of Aluminum Welding in the Auto Industry

The drive to make vehicles lighter and more efficient while retaining durability and usefulness has led to a push to increase the use of aluminum in the building of vehicles, more so than ever before. While aluminum has been a key material in vehicle production for nearly a century, recent changes by major car makers such as General Motors and Ford have really increased the use of it.

Topics: Aluminum Welding, Laser Welding

/Blog%20Photos/3%20Things%20You%20Need%20To%20Know%20When%20Welding%20With%20Aluminum/3ThingsYouNeedToKnowWhenWeldingWithAluminum.jpg)

.png)