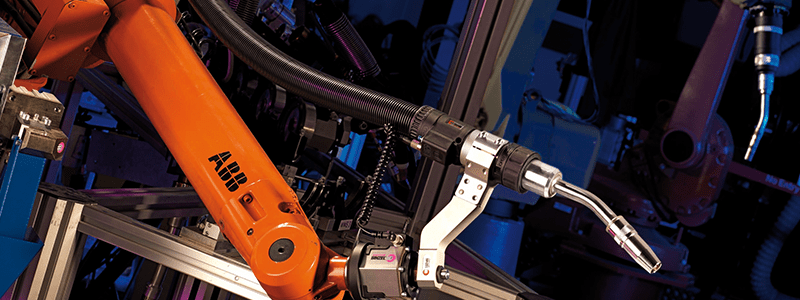

When it comes to your robotic welding torch, the swanneck (sometimes known as the gooseneck or torch neck) is one of your most critical parts. What is a swanneck? It is the front end or “working end” of a robotic welding torch, where the contact tip and gas nozzle are mounted to deliver the electrical current, filler wire, and shielding gas into the weld joint.

Jim DiLeo

Recent Posts

Robotic Welding Torch Swanneck Breakdown: Build, Design, and Construction

Topics: Robotic Welding

Fume Extraction System Problems and Solutions

Fume extraction systems are big investment for your plant. Especially when using either a single station or multi-station fume extractor, it's bound to encounter problems at some point during it's service life.

That's normal and you shouldn't be surprised by that.

Topics: Fume Extraction

The Atlantic Says Welding Won't Make You Rich. Are They Right?

When I read this article from The Atlantic last week on welding salaries and the posits of people proclaiming over the last few years that welders can make $150,000 USD a year, I remembered the countless Instagram and Facebook memes I see claiming similar promises of comfortable lifestyles by getting into one of the more admirable and skilled trades professions out there, and all the welders commenting about that decidedly not being the case.

Topics: News React

Understanding MIG Welding Nozzles

With your MIG gun you have a variety of welding nozzle designs to choose from, and sometimes the decision on which to choose is not always clear.

Topics: Welding Consumables

How Much Does a Robotic Torch Cost?

So what does a robotic torch cost? You probably browse some of the welding equipment supplier websites and never see a price on those sites (ours included!), but then go to a welding distributor website or browse through their catalogs and get the List price from them. How do you know what you're paying for?

Topics: Robotic Welding

How to Correctly Capture Weld Fumes at the Source

Gas metal arc welding (GMAW) is one of today’s most popular welding methods in nearly all industrial manufacturing fields. This is a positive development; however, the process has a wide range of risks for the welder. Welders protect themselves from the negative effects of welding by wearing protective gear to protect the body and eyes from burns, electrical shock and bright light and ultraviolet radiation.

Topics: Fume Extraction

.png)