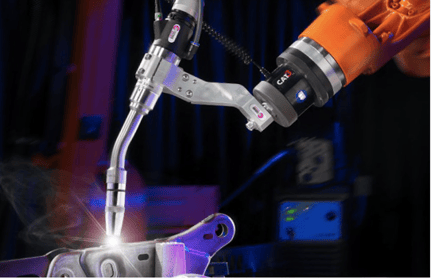

When it comes to your robotic welding torch, the swanneck (sometimes known as the gooseneck or torch neck) is one of your most critical parts. What is a swanneck? It is the front end or “working end” of a robotic welding torch, where the contact tip and gas nozzle are mounted to deliver the electrical current, filler wire, and shielding gas into the weld joint.

The function of a swanneck is crucial to the success and efficiency of your operation. Repeatability is a word used frequently when discussing robots and one you will hear often when discussing the design of a robotic swanneck. If your swanneck cannot deliver consistent welds, you are going to start running into problems.

Build, Design, and Construction

Swanneck designs have the ability to alter your operation in a matter of minutes. Consider the following – Does the swanneck hold up from a crash? Will minor collisions cause the swanneck damage that cannot be reversed? Will the crash cause a bend?

The build of a swanneck is unique in a number of ways. From the shape of the neck, consideration of the keying, and overall construction of single vs. multiple pieces, each swanneck can look and operate differently depending on how you choose to design it.

Starting off easy, a basic swanneck will either be straight or bent at an angle. The two most common angles are 22 and 45 degrees. For overarm robot installations, a 22-degree swanneck is usually paired with a 23-degree offset mounting arm to give an approach angle of 45-degrees to the weld joint.  The 45-degree swannecks are most commonly used with a hollow wrist style robot. The bend in the swanneck also ensures a cast in the wire for optimal electrical contact in the tip.

The 45-degree swannecks are most commonly used with a hollow wrist style robot. The bend in the swanneck also ensures a cast in the wire for optimal electrical contact in the tip.

Robotic swannecks are almost always manufactured with an interface keying system. This keyway is to ensure repeatability when removing and replacing these necks, so operators do not have to do any reprogramming of the robot. This repeatability of the tool center point (TCP) allows for minimum downtime of production.

The location of wear points is a crucial factor when it comes to keying. Wear point locations on a robotic torch can impact the durability of the torch. When the wear points (specifically soft keyways) are located on the front module of the robot torch, then the integrity of the front module erodes the swannecks durability and the neck will start losing its TCP. Some manufacturers include dual keyways or a combination of key ways and locating dowel pins for added TCP precision and durability.

Ideally, you would want multiple wear points located on the neck. In the case that the robotic torch fails with repeatability, you will be able to replace the swanneck rather than the front module. Being able to make changes or do maintenance to your torch without worrying about TCP variance is what can set you apart from others. The uptime, throughput, and ROI will justify the purpose of the ideal keyway design.

Air-Cooled and Water-Cooled Swannecks

The two most common uses of a swanneck are for air-cooled and water-cooled welding guns. Air-cooled swannecks rely on ambient air and shielding gas to cool them down from the heat generated during the welding process. On the other hand, water-cooled swannecks rely on coolant circulating through inner layers to cool it down, thus making it more efficient. Both air-cooled and water-cooled swannecks are precisely bent to specified angles after the layers of each are assembled.

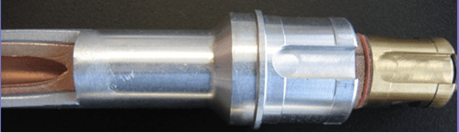

The typical design for an air-cooled swanneck has 3 layers. The inner most layer is usually a copper tube, followed by an insulating layer, closed off with the outer layer.

The inner tube is made of copper because it has efficient electrical conductivity. Some manufacturers use thicker-walled copper tubes than others to increase heat management and provide additional durability.

The middle layer, or insulation layer, prevents the outer layer from becoming electrically live. If this layer is not included or becomes damaged in a crash, there is potential for arcing at the swanneck instead of the weld joint - as electricity takes the path of least resistance.

The outer layer of air-cooled necks is most commonly made of aluminum, but can sometimes be steel tubing. This metal type is used to help radiate the heat more efficiently. Some manufacturers use a thin-walled tube that is crimped to the inner and insulating layers. Look for a machined aircraft grade aluminum neck with thicker walls to increase durability for maintaining TCP.

Examples of Air-cooled swannecks. In the top image, notice the dual keyway and thick copper inner tube with machined aluminum outer layer. The lower example shows crimped construction with thinner inner and outer layers.

Examples of Air-cooled swannecks. In the top image, notice the dual keyway and thick copper inner tube with machined aluminum outer layer. The lower example shows crimped construction with thinner inner and outer layers.

Swannecks created for water-cooled equipment typically have multiple layers. They also have coolant lines machined into the inner layers to allow coolant flow with the use of a re-circulator, or more commonly known as a water-cooler.

The layer within a water-cooled swanneck is made of copper and/or brass. They can have a single or double layer with coolant flow. The double layer allows for improved cooling in higher heat applications. In addition to this, they include insulation so the outer layer is not electrically live during welding. The inner layers are usually brazed or silver soldered together.

Interested in learning more about Robotic Welding Torches? Check out our Definitive Guide To Robotic Welding Torches eBook!