As material and fabrication technologies evolve, manufacturers are pushing the limits of the structures used in automotive, construction, offshore, energy production, and many other industries. All of these industries use welding in their day-to-day production tasks, and, because welds are used to join two or more metal surfaces, these connections may encounter loads and fatigue during product lifetime. There is always a chance these products may fail, if not created to proper specification.

How Automated Weld Quality Assurance Increases Productivity

Topics: Laser Welding, Automation

Weld Process Monitoring for Industry 4.0

Industry 4.0 is all about the ongoing transition into an even smarter, automated manufacturing world, using new developments in technology to get us there. Through the use of intelligent, automated technology, we are able to communicate more efficiently, collect data with advanced traceability, and create human-like interactions between machines and computers.

Topics: Robotic Welding, Laser Welding, Automation

Getting Started with Laser Welding

With the rise of laser welding, the importance of understanding this process is absolutely critical. Once you have the basics down, you can begin to consider what it would take to incorporate this type of welding equipment into your facility.

Like anything new, a great start to learning is determining the advantages and disadvantages that come along with whatever you’re dealing with; in this case laser equipment as it relates to welding.

Topics: Laser Welding

How Does Laser Welding Work?

Understanding the process of laser welding can be intense and somewhat confusing, especially if you are just getting acclimated to this welding application type. To get started, let’s first address how a laser works and why they may be useful in a welding setting.

Topics: Laser Welding

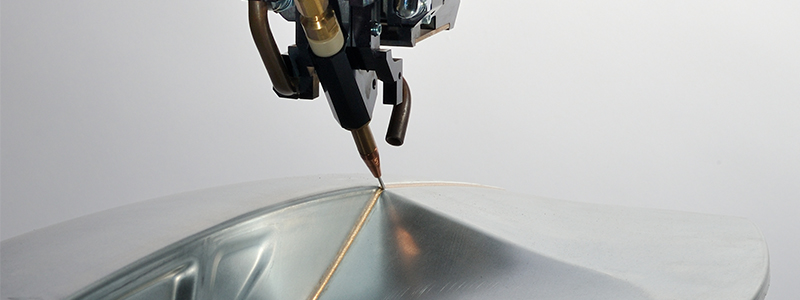

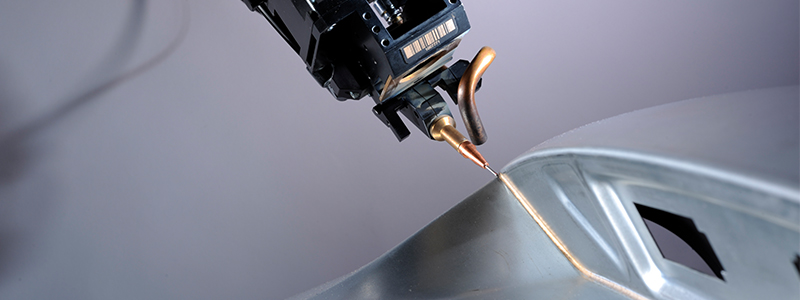

Feeding Wire in Laser Welding Applications

Wire feeding in laser metal joining applications is all about precise wire positioning relative to a laser beam and accuracy in wire feeding speed. Wire feeding system layout and configuration are key parts in ensuring a successful application that makes the communication between user, integrator, and equipment manufacturers, at early project stages, highly important for a laser metal joining cell performance.

Topics: Laser Welding

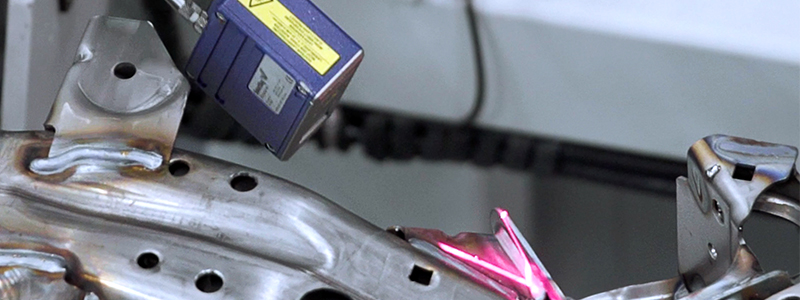

Seam Tracking for Laser Welding and Brazing

One of the biggest hurdles in any automated joining system is the ability to find and track the joint in a consistent nature. Joint quality can be poor due to a number of variables including the standard variance in upstream parts supply or simply poor joint design from either a process or product perspective. Firstly, there is the variation that is inherent in single parts and the overall stack up.

Topics: Laser Welding

The Rise of Aluminum Welding in the Auto Industry

The drive to make vehicles lighter and more efficient while retaining durability and usefulness has led to a push to increase the use of aluminum in the building of vehicles, more so than ever before. While aluminum has been a key material in vehicle production for nearly a century, recent changes by major car makers such as General Motors and Ford have really increased the use of it.

Topics: Aluminum Welding, Laser Welding

.png)

.png)

.png)