When it comes to providing value through collaboration, the duo of ABB Robotics and ABICOR BINZEL does just that by innovating and integrating automation solutions for you.

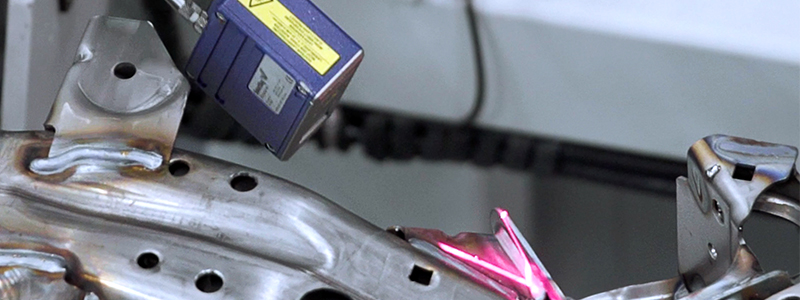

With a top-of-the-line ABB robot, with welding torches and peripherals added to the table from BINZEL, customers can be sure they are receiving the highest-quality welding equipment available.

/Landing%20Pages/Partners%20and%20Relationships%20Page/800x300_ABB_01.jpg)

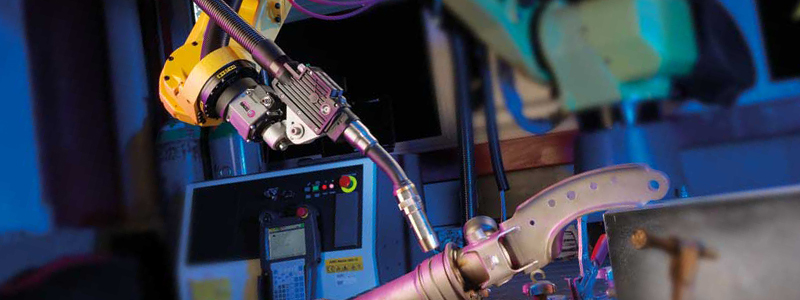

/Landing%20Pages/Partners%20and%20Relationships%20Page/800x300_Yaskawa_01.jpg)

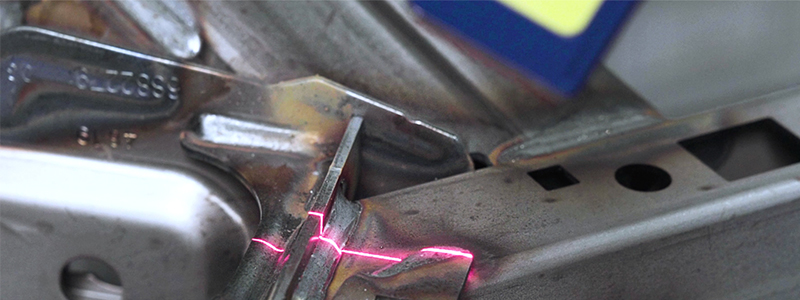

/Blog%20Photos/Novarc%20x%20Binzel/SWR.jpg)