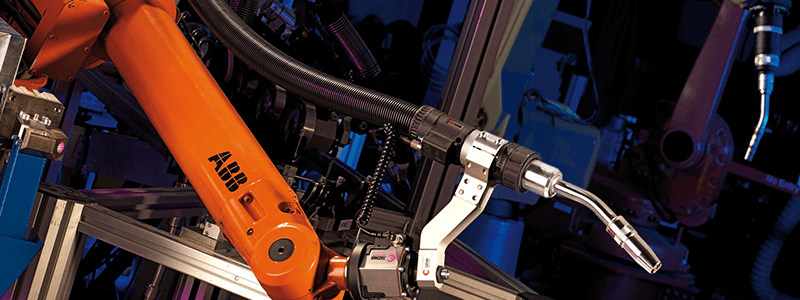

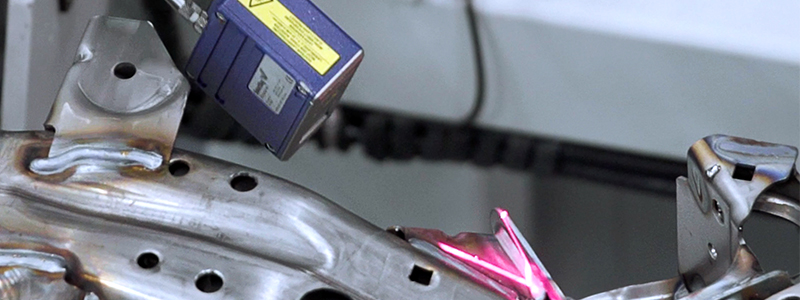

The future of manufacturing is here, and it's being shaped by collaborative robots, specifically cobot welders. These machines are revolutionizing welding solutions, making welding faster, easier, and more efficient.

If you're thinking of investing, you're probably wondering: what's the real cost of bringing these advanced welding systems on board? Let's dive into the factors that drive the price and explore what you can expect to invest.

.png)

-2.png)

-2.png)