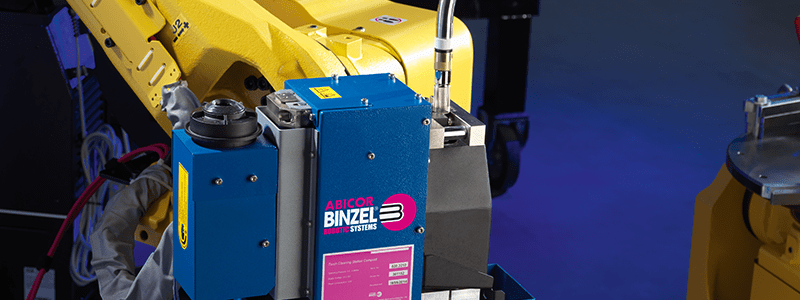

Novarc Technologies and ABICOR BINZEL USA, Inc. are pleased to announce the world’s first collaborative Spool Welding Robot (SWR) is now available for demonstrations at Har-Bach (formerly known as Red Rock USA) in Houston, Texas.

BINZEL USA Teams with Novarc Technologies for collaborative Spool Welding Robot

Topics: Company News

5 Tools Every Robotic Welding Torch Should Have

Robotic welding torches can streamline the welding process and make it a more reliable and faster production. But robotic welding cells and the torch itself is only as good as what you surround it with. Beyond talented personnel, there are tools every welding robot and robotic torch could use to make automated welding a more effective and efficient process.

Topics: Robotic Welding

How Much Does a Robotic Torch Cost?

So what does a robotic torch cost? You probably browse some of the welding equipment supplier websites and never see a price on those sites (ours included!), but then go to a welding distributor website or browse through their catalogs and get the List price from them. How do you know what you're paying for?

Topics: Robotic Welding

MIG Gun Welding Diffusers: Copper vs. Brass

We often see different materials used for welding torches and their consumables. Mostly you can see Brass and Copper or Copper alloy - depending on the needs. Since there are various Copper alloys, we focus on the Copper Alloy: CuCr1Zr. Remember also that Brass, which is known as an alloy from Copper and Zinc, has many variations, as well. We will work with an example here.

Topics: Welding Consumables

4 Problems with Fume Extraction MIG Guns (and How to Overcome Them)

We get it, not everyone loves fume extraction torches. For one reason of another, whether you're a welder or a welding engineer or a project manager, the same problems or complaints come up when it comes to fume guns.

Topics: Fume Extraction

4 Problems with MIG Guns and How to Overcome Them

Most MIG guns are designed to last. Problem is, a lot of welders and welding professionals don’t believe it. There are ‘problems’ with MIG guns – and specifically lightweight ones. They can have a bad rap, or are misunderstood. Light doesn’t mean weak. In fact, a lot of times it’s just the opposite.

Topics: MIG Guns & Torches

3 Problems with Contact Tips and How to Solve Them

Usually when I'm meeting with a Foreman or Production Manager and get a chance to talk first hand to his or her welders, one of the most common topics that come up is their contact tips. The problem: they have to change them too much. This kills productivity for the shop, takes a big bite out of cost, and generally just creates a less efficient atmosphere for the welder to work in.

Topics: Welding Consumables

Why Should You Use a Premium MIG Gun?

When I meet a customer for the first time I like to ask them first and foremost about the torches they currently use. Most of the time they answer the question something like this:

Topics: MIG Guns & Torches

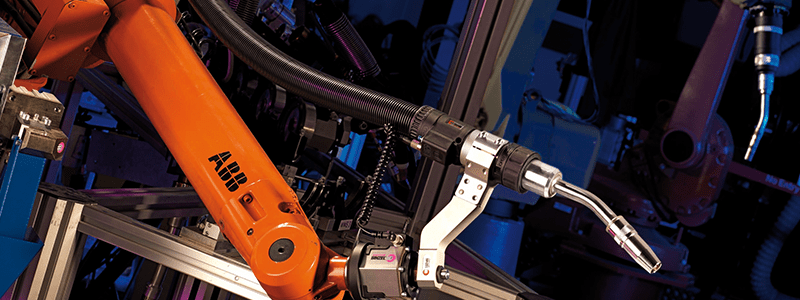

Air-cooled vs. Water-cooled for Robotic Welding Torches

When it comes to robotic MIG welding you often have to ask the question about whether you should go air-cooled or water-cooled. It's always good to have the right tool in the right place for both optimal performance and cost. Looking at water-cooled versus air cooled, there are obvious cases where you would choose one over the other.

Topics: Robotic Welding

Robotic Welding Cable Assemblies: Telling a Good One from a Bad

When you think of welding automation, cable assemblies are probably not the highest priority when evaluating options. But you may be overlooking a critical part of the torch as you go through all the different robot torch options out there. Without question, the quality of your cable assembly plays a key role in maximizing the efficiency of your automated welding processes.

Topics: Robotic Welding

/Novarc%20Technologies/Banners/Spool_Welding_Robot_Noir.png)

.png)

.png)

.png)

.png)

-1.png)

-1.png)