When considering an automated welding process, fully or semi-automated, it is important to consider and compare the advantages and disadvantages of both for your operation, and how well each may (or may not) integrate into your established welding process. Sometimes, deciding one way or the other is very clear based on the kinds of welds being performed, and other times it’s a matter of how much productivity you need to meet your goals.

Flexible or Hard Automation? Why?

Topics: Hard Automation

3 Reasons Why Welding Tractors Make Your Life Easier

In fabrication, productivity is everything; anytime you have the opportunity to make your welding process more efficient and cost effective, you should consider that direction, and welding tractors do exactly that. Considering ways to improve productivity can be frustrating, so we’ve done the work for you.

In this article we are going to give you three reasons why welding tractors make your life easier.Topics: Hard Automation

Robotic Welding Troubleshooting Tips

When it comes to weld cell issues, oftentimes it is the simple things that are affecting its performance. Being able to know the basics and go through the basics will usually solve the vast majority of your robotic torch performance problems.

Topics: Robotic Welding

How to Test Your Fume Extraction System

With fume extraction welding, the effectiveness of the smoke capture is always dependent on the strength of the fume extraction system. No matter how effective the torch or skilled the welder, without a system strong enough to capture the smoke, both the welder and the environment will not be spared from the harmful effects of metallic fumes.

Topics: Fume Extraction

Why is My MIG Wire Feeding Improperly?

If your MIG wire isn’t feeding smoothly, there are a few key things to consider. This MIG welding troubleshooting guide will walk you through the most common MIG welding issues and how to resolve them.

Topics: MIG Guns & Torches

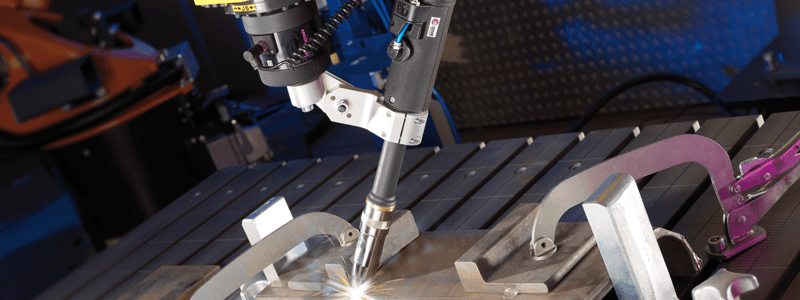

A Brief Guide on Wire Brakes for Robotic Welding

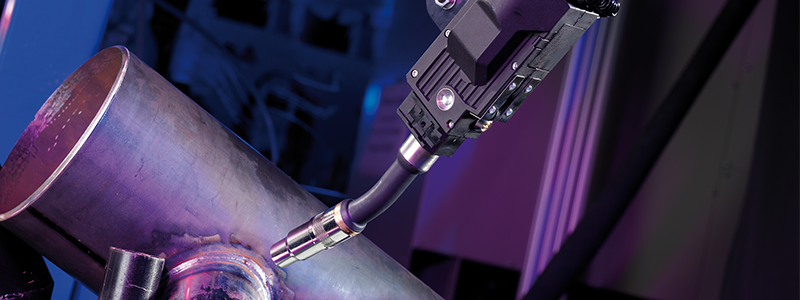

Robotic welding torches with integrated wire brake are designed for use in robotic welding applications utilizing the weld wire to touch sense weldment parts (i.e. check for part placement and/or fit up).

Topics: Robotic Welding

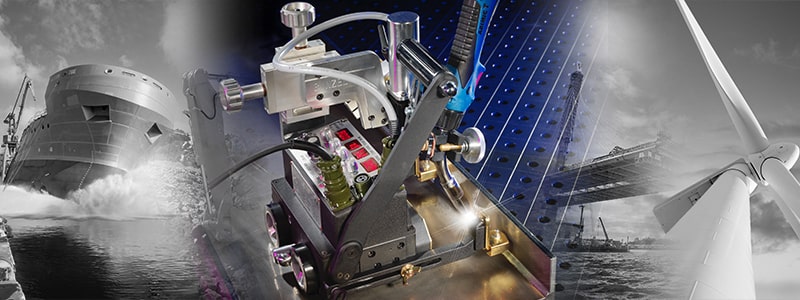

Spool Welding Robot: FAQs

When you see a solution like the collaborative Spool Welding Robot, there are sure to be questions. Some simple, some more complex. Based on your feedback, we've compiled the 23 most frequently asked questions on the collaborative Spool Welding Robot to answer for you.

Topics: Pipe Welding

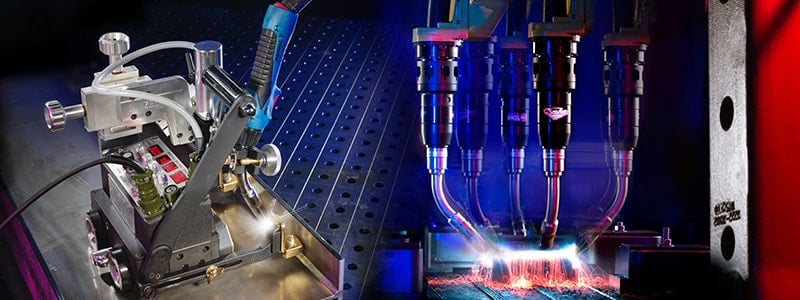

5 Signs it's Time to Automate Your Pipe Welding

As a fabricator, you may experience growing pains as your company handles increased demand. These pains often include productivity and labor issues, and pipe welding automation is an excellent solution to eliminate them. But how do you know when to automate your pipe welding? Below are five signs you may need to automate:

Topics: Pipe Welding

Why Electronic Gas Management is Poised to Improve the Cost of Welding Gas

Gas delivery and gas management is inefficient and in need of some innovation. Looking at the landscape of gas delivery and gas management optimization, there’s very little invested or innovated in the actual deliverance of gas from supply tank through the control device and out the welding nozzle.

Topics: Shielding Gas

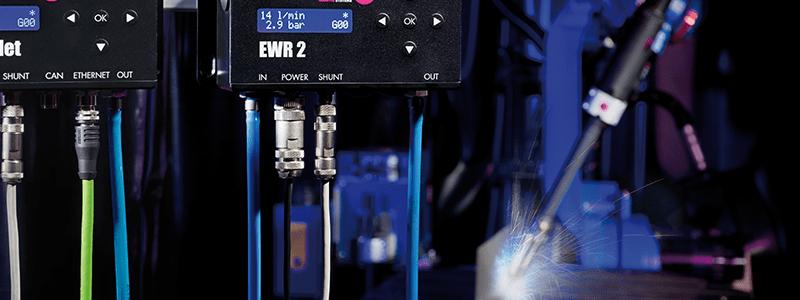

Gas Management System EWR 2: Frequently Asked Questions

When version one of the Electronic Welding Regulator EWR was released, we received a lot of questions about it's performance and how exactly it works to control the flow of shielding gas.

Now with version 2.0 of the EWR out - the EWR 2 / EWR 2 Net - we wanted to answer some of the frequently asked questions we received on the original EWR and update it for the next generation of gas management:

Topics: Shielding Gas

/Novarc%20Technologies/Banners/Spool_Welding_Robot_Programming.png)

/Novarc%20Technologies/Banners/Spool_Welding_Robot_Positioner.png)