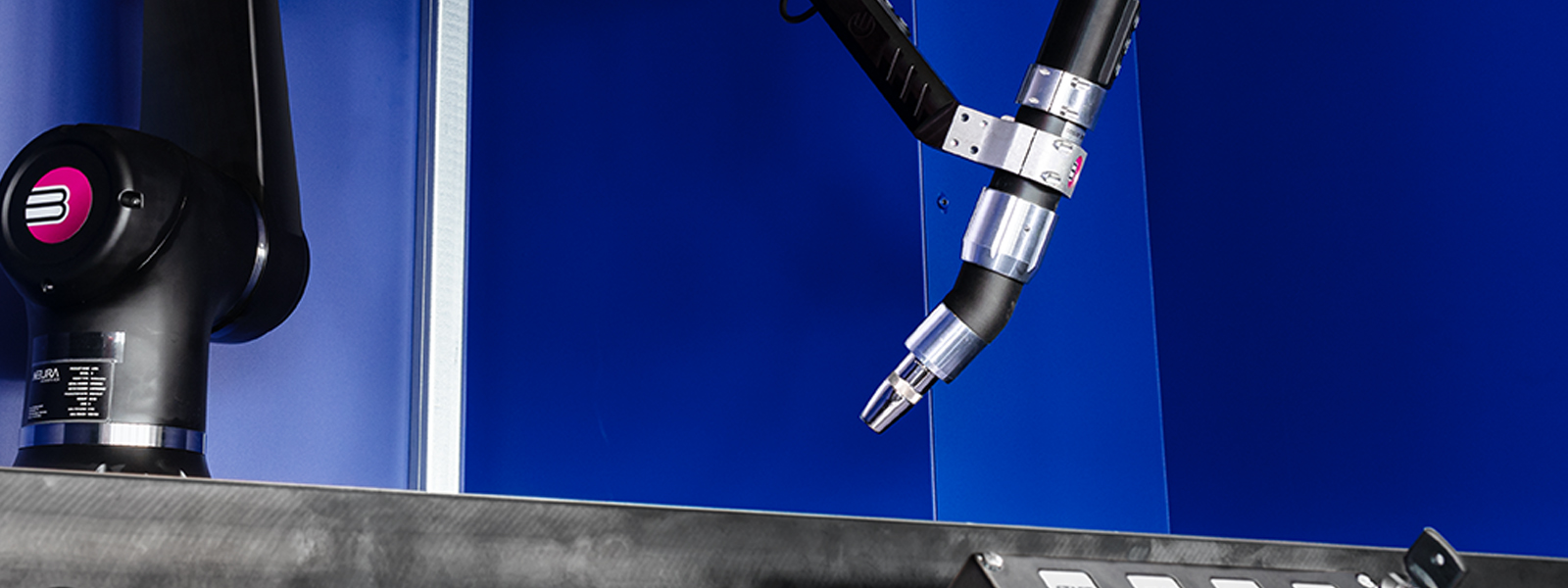

Welding with collaborative robots or cobots, introduces unique safety challenges that require careful planning and proactive measures. Implementing key safety practices can protect workers and maintain a safe work environment.

Ensuring Safe Welding with Collaborative Robots

Topics: Robotic Welding, Automation

Cobots: Revolutionizing Welding Amid Skilled Worker Shortage

In recent years, the manufacturing industry has faced a significant challenge – a shortage of skilled welders. As businesses strive to maintain and improve their welding processes, many are turning to innovative solutions, and one technology is standing out: collaborative robots, or cobots. Let's dive into how cobots, are addressing the shortage of welders and bringing significant value to businesses through the welding process.

Topics: Robotic Welding, Automation

Safeguard Your Welders and Maximize Efficiency Without the Fume

In the fast-paced world of welding, staying ahead of market demands is crucial. The team at ABICOR BINZEL USA is committed to continuously expanding their range of top-notch welding fume extraction solutions. The latest addition to their impressive lineup is a robotic welding torch xFUME® ABIROB® AF500, which integrates seamlessly into your robotic welding cells.

Topics: Robotic Welding, Fume Extraction, MIG Guns & Torches, Company News, Products, New Product Release

Fume Extraction: What Is It? Why Do I Need It?

Maximize safety and efficiency in your welding shop with ABICOR BINZEL's xFUME® line - the ultimate solution for fume extraction.

Topics: Robotic Welding, Fume Extraction, MIG Guns & Torches, Company News, Products, New Product Release

Efficient Fume Extraction MIG Welding Without the Weight

We at ABICOR BINZEL USA continue to add to our ever-expanding line of high-quality welding fume extraction solutions with the latest addition being the xFUME® PRO lightweight fume extraction MIG gun!

Topics: Fume Extraction, MIG Guns & Torches, Company News, MIG/MAG, Products

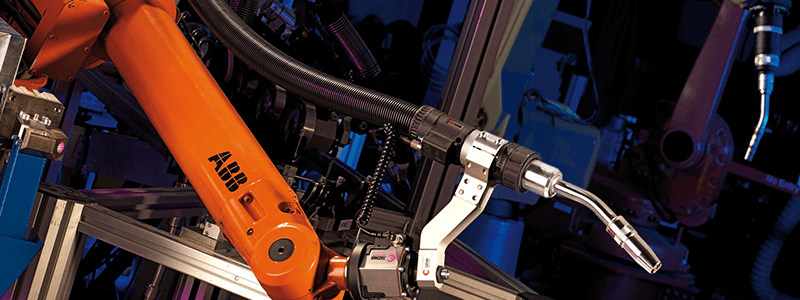

Robots & Robotic Welding Torches | ABB Robotics x ABICOR BINZEL

As technology advances, your workplace must adapt to keep up with the need. That period of adapting will look different for everyone, as some operations needs are on a much smaller scale than others. For those in larger manufacturing plants, the push to automate has become a more prevalent move. Productivity is the name of the game and to keep up, operations must be able to repeat their tasks quickly and efficiently.

Topics: Robotic Welding, Automation

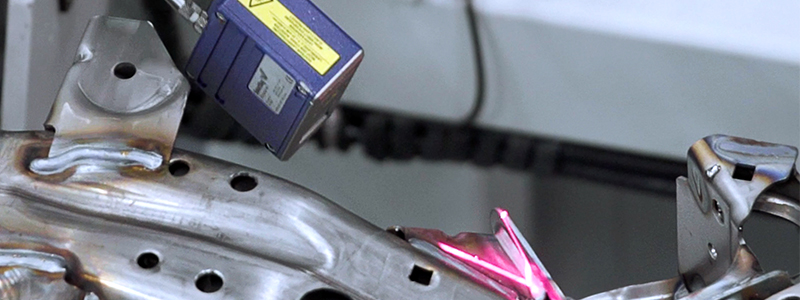

Automated Weld Inspection with BINZEL and SmartRay

Weld inspection is a topic discussed time and time again, as many debate what the best process is and why it will provide the best overall result. This is where the collaboration between SmartRay and ABICOR BINZEL comes into play.

Topics: Automation, Weld Inspection

Seam Tracking and Welding Peripherals: ABICOR BINZEL x Yaskawa Motoman

With the current state of the welding industry as it sits now, we are seeing a lot of manufacturers moving away from manual to create a more automated process. With this comes a host of new welding equipment that can benefit your process, from improving repeatability and traceability, to increasing productivity and general performance.

Topics: Robotic Welding, Automation

Seam Tracking and Automation Solutions | BINZEL x ABB Robotics

When it comes to providing value through collaboration, the duo of ABB Robotics and ABICOR BINZEL does just that by innovating and integrating automation solutions for you.

With a top-of-the-line ABB robot, with welding torches and peripherals added to the table from BINZEL, customers can be sure they are receiving the highest-quality welding equipment available.

Topics: Robotic Welding, Automation

Robotic Welding with ABICOR BINZEL & Yaskawa Motoman

ABICOR BINZEL manufactures high quality MIG welding products and peripheral equipment, from torch cleaning stations to torch exchange stations. In addition, BINZEL has a complete line of sensors, from laser seam tracking to automated weld inspection.

Topics: Robotic Welding, Automation

-2.png)

/Blog%20Photos/Efficient%20Fume%20Extraction%20MIG%20Welding%20Without%20the%20Weight/Efficient_Fume_Extraction_MIG_Welding_Without_the_Weight.jpg)

/Landing%20Pages/Partners%20and%20Relationships%20Page/800x300_ABB_01.jpg)

/Landing%20Pages/Partners%20and%20Relationships%20Page/800x300_Yaskawa_01.jpg)