Automation is one of the leading trends in the pipe welding industry today because pipe fabrication shops are looking for ways to increase productivity and quality, while trying to combat the shortage of qualified welders. ABICOR BINZEL has partnered with Novarc Technologies to resolve this problem and provide a meaningful solution that improves this production process. BINZEL serves as Novarc's global sales and service partner for the Spool Welding Robot (SWR), continuing our efforts to provide exceptional product and service quality. This partnership is delivering massive productivity and quality increases, making our customers more competitive in the markets they serve.

Automation in Pipe Welding: ABICOR BINZEL x Novarc Technologies

Topics: Pipe Welding, Robotic Welding, Automation

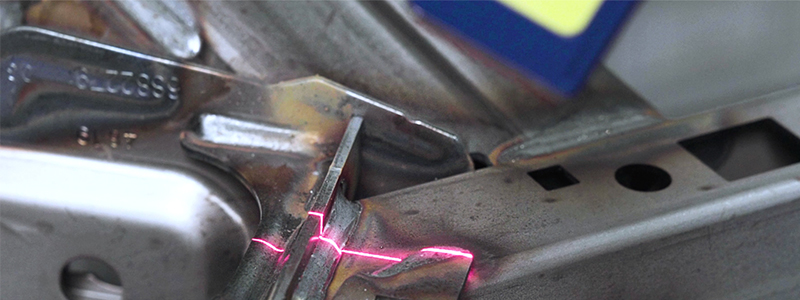

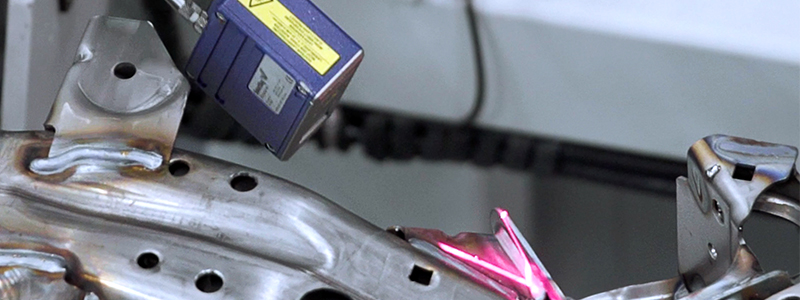

How Automated Weld Quality Assurance Increases Productivity

As material and fabrication technologies evolve, manufacturers are pushing the limits of the structures used in automotive, construction, offshore, energy production, and many other industries. All of these industries use welding in their day-to-day production tasks, and, because welds are used to join two or more metal surfaces, these connections may encounter loads and fatigue during product lifetime. There is always a chance these products may fail, if not created to proper specification.

Topics: Laser Welding, Automation

Weld Process Monitoring for Industry 4.0

Industry 4.0 is all about the ongoing transition into an even smarter, automated manufacturing world, using new developments in technology to get us there. Through the use of intelligent, automated technology, we are able to communicate more efficiently, collect data with advanced traceability, and create human-like interactions between machines and computers.

Topics: Robotic Welding, Laser Welding, Automation

Getting Started with Laser Welding

With the rise of laser welding, the importance of understanding this process is absolutely critical. Once you have the basics down, you can begin to consider what it would take to incorporate this type of welding equipment into your facility.

Like anything new, a great start to learning is determining the advantages and disadvantages that come along with whatever you’re dealing with; in this case laser equipment as it relates to welding.

Topics: Laser Welding

How Does Laser Welding Work?

Understanding the process of laser welding can be intense and somewhat confusing, especially if you are just getting acclimated to this welding application type. To get started, let’s first address how a laser works and why they may be useful in a welding setting.

Topics: Laser Welding

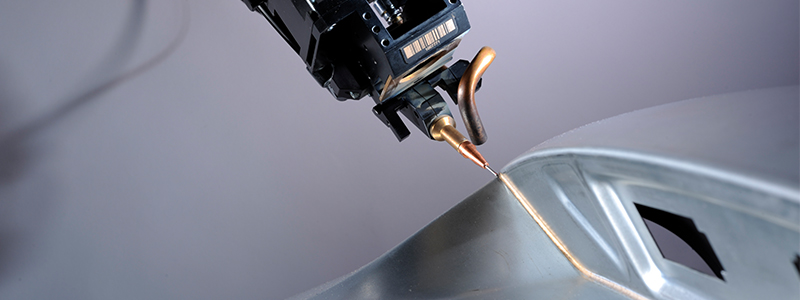

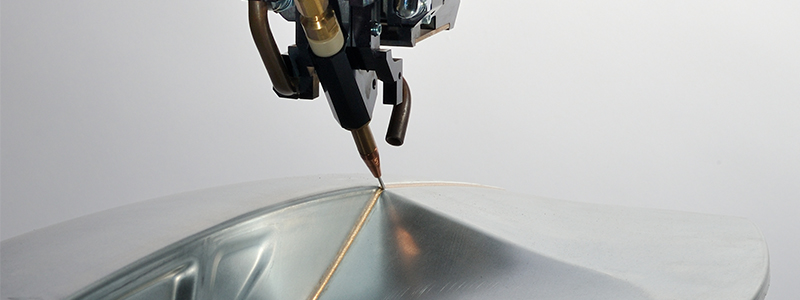

Feeding Wire in Laser Welding Applications

Wire feeding in laser metal joining applications is all about precise wire positioning relative to a laser beam and accuracy in wire feeding speed. Wire feeding system layout and configuration are key parts in ensuring a successful application that makes the communication between user, integrator, and equipment manufacturers, at early project stages, highly important for a laser metal joining cell performance.

Topics: Laser Welding

Why You Should Integrate Automated Weld Inspection Into Your Process

When it comes to weld inspection, this portion of your weld process is among the most crucial. With a majority of facilities using visual weld inspection methods to pass welds as good or bad, you encounter a major inconsistency issue and run the risk of missing bad welds.

Topics: Weld Inspection

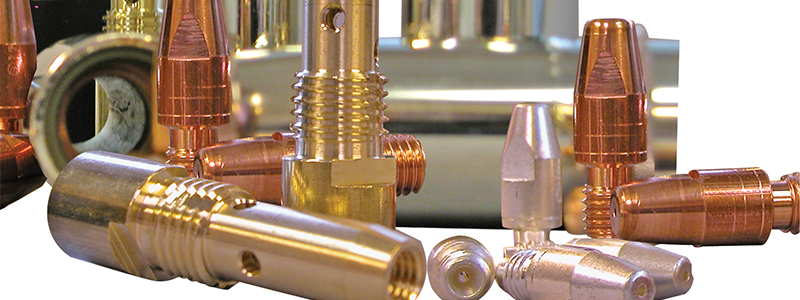

The Best Consumables For Aluminum Welding

Aluminum welding has become one of the most popular forms of welding in the industry today, with a special interest being in the automotive sector. Understanding how to successfully weld aluminum becomes the tricky part, as it is not the easiest material to work with. The process as a whole has its challenges, from preparation and correct welding techniques to specific equipment that should be used to help your operation run smoothly.

For this reason, aluminum requires specific consumables to ensure your welding jobs are completed with minimal issues and ease. In this blog, we will break down the necessary consumables needed to properly weld aluminum.

Topics: Aluminum Welding

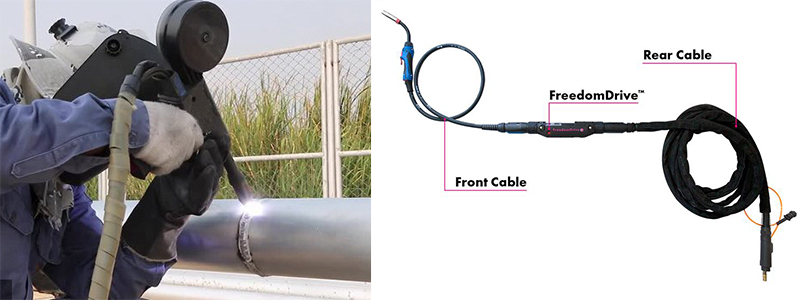

The Problems With Push-Pull & Spool Guns That FreedomDrive™ Solves

Those experienced in push-pull welding understand the challenges that can arise when using this type of equipment. When it comes to ensuring consistent and problem-free wire feeding, you can frequently experience issues or limitations - some being tied specifically to your push-pull welding gun.

Topics: Aluminum Welding, MIG Guns & Torches

Common Problems in Aluminum Welding and How to Resolve These Issues

As aluminum welding remains a rising force in the industry, continuing to test and understand the problems that come along with it is essential. With all the advantages that aluminum brings, there are also some aspects of this material that makes it tricky to weld with. For starters, aluminum is very soft, leading to many of the issues we will discuss.

Topics: Aluminum Welding

/Blog%20Photos/Novarc%20x%20Binzel/SWR.jpg)

.png)