Welding can be a challenge, especially when it comes to meeting position tolerances. Poorly prefabricated components, clamping issues, and heat distortion can all throw a wrench in the works. Sound familiar?

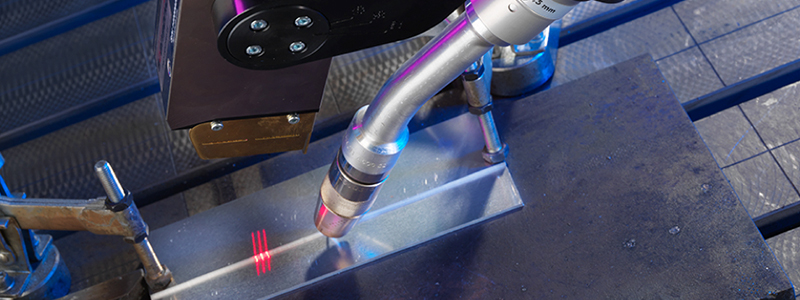

Mastering Welding Tolerances: The Power of Seam Tracking

Topics: Robotic Welding, Seam Tracking

How do I Choose the Right Seam Tracking Sensor?

Are you considering investing in a seam tracking sensor for automated welding, but are unsure where to begin? You're in the right place! This blog provides a comprehensive starting point for understanding what makes an excellent seam tracking sensor and when to invest. To achieve flawless welds, robots need precise guidance, which is where seam tracking sensors come in. In this blog, we'll explore the essential properties of top-notch seam tracking sensors.

Key Sensor Properties Covered:

- Precision

- Reliability

- Flexibility

- Ease of Use

Topics: Seam Tracking

Weld Joint Finding Methods Explained

When we look at weld joint detection and the benefits involved, there are two primary features of these technologies: the finding and tracking of the joint.

Topics: Seam Tracking

How Seam Tracking Solutions Compare

Looking at Seam Tracking means looking at a variety of possible solutions. Depending on your process, material, and cycle time needs, the right solution will usually present itself over time.

But with if you aren't aware of ALL the solutions available?

Or just know about a couple?

Topics: Seam Tracking