A well maintained MIG torch is a crucial component for weld efficiency. A damaged or worn-out torch can lead to reduced labor productivity, reduced quality, and increased costs. In this blog, we'll explore five simple yet effective ways to extend the life of your MIG torch.

Recent Posts

5 Ways to Increase Longevity in your MIG Torch

Topics: MIG Guns & Torches

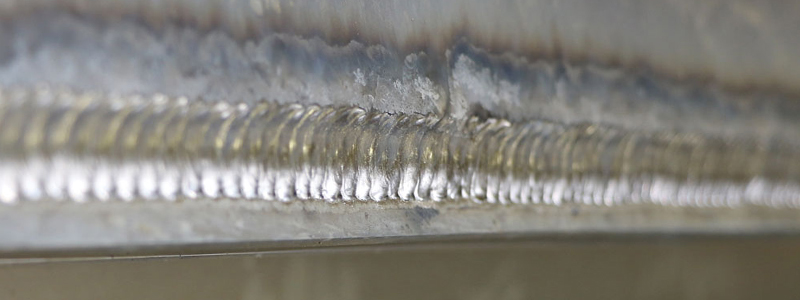

Common Problems in Aluminum Welding and How to Resolve These Issues

As aluminum welding remains a rising force in the industry, continuing to test and understand the problems that come along with it is essential. With all the advantages that aluminum brings, there are also some aspects of this material that makes it tricky to weld with. For starters, aluminum is very soft, leading to many of the issues we will discuss.

Topics: Aluminum Welding

Do I Need A Spool Gun to Weld Aluminum?

There is no question that aluminum has special characteristics that require it be welded different than other metals. Aluminum is a very soft metal, with a high melting point that requires high voltages. Distorting aluminum is easy and can happen pretty quickly, as the wire will start oxidizing almost immediately, leading to a host of issues. Spool guns were designed to help feed difficult wire in an effort to avoid messy welding by placing the feeder right on the gun. Reliable wire feeding is among the most important parts of welding.

Topics: Aluminum Welding

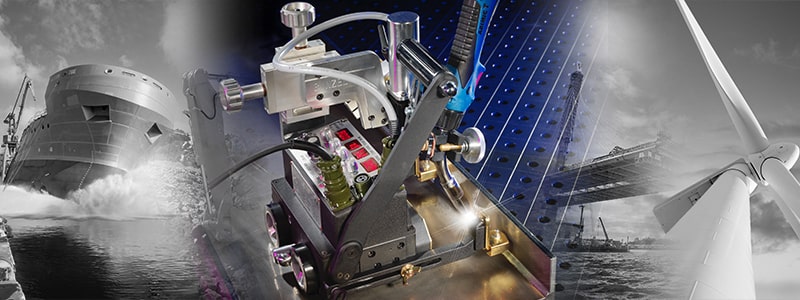

3 Reasons Why Welding Tractors Make Your Life Easier

In fabrication, productivity is everything; anytime you have the opportunity to make your welding process more efficient and cost effective, you should consider that direction, and welding tractors do exactly that. Considering ways to improve productivity can be frustrating, so we’ve done the work for you.

In this article we are going to give you three reasons why welding tractors make your life easier.Topics: Hard Automation

-1.png)