Let's face it: for most people looking at Fume Extraction, many of them have never seen fume extractions solutions before aside from extractor arms.

That means most Safety Managers, Production Managers, or business Owners - and I may be talking to you directly - don't even know what questions to ask themselves before getting started.

For them, it's usually as simple as:

I have a weld fume problem, how do I solve it?

Does that sound like you? If it is, you're like almost everybody else when it comes to getting started with fume extraction.

So what should you know before someone brings a solution to your business? What questions do you need to know the answers to? And why do those answers matter in how fume extraction may be implemented in your business?

Fortunately for you, we've done our own research on the questions people don't typically have the answers to when we visit to introduce fume extraction. These are those five questions you should know, why they're important:

-

What's the end goal for fume extraction in the workplace?

-

How many fume extraction torches are required?

-

What are the welding parameters?

-

Where is power available (and is it the right power)?

-

What is the status of the building

What is the end goal for fume extraction in the workplace?

Knowing why you are looking at fume extraction is crucial for helping to guide you to the right solution. Reducing fume within your space is a different end goal than needing to remove something like manganese or hexavalent chromium.

To reduce fume means capturing weld fumes but the end goal being more subjective than measured or recorded. This could mean solutions as simple as fume extractor arms or introducing fume extraction torches with a mid-power vacuum unit that produces a high but unmeasured level of fume extraction.

If it’s removing manganese or hex chromium, it is a far more serious challenge that has to be met with a series of steps. That would include things like having a hygienist evaluate the plant and work closely with a solutions provider to get air quality to an acceptable level.

A combination of solutions may be required, such as source capture fume extraction with an ambient air system.

At the very least, a fume extraction torch with a high-powered extraction system would be evaluated, and at least 90% of fumes would likely need capturing for plant air quality to be at an acceptable level if not more.

How many fume extraction torches are required?

It may seem like a simple question, but the number of torches you are considering has a big impact on the type of fume extraction system that will be recommended to you. Why is this the case? It impacts if a portable or centralized fume extraction system is going to be the most cost effective and performance-friendly solution for you.

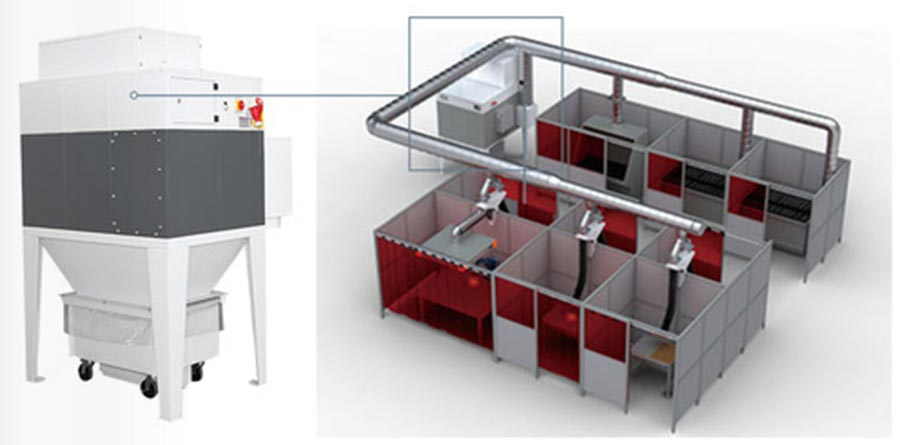

Generally speaking, if you are looking at a handful of welding guns to convert over, your best course of action is to utilize portable vacuum systems. If you have a larger plant and several welding stations to convert, a centralized system is the preferred solution, even with the higher upfront capital cost. Reason being is there is less overall maintenance and the cost of owning it is considerably less after the initial investment.

The only difference between a standard MIG gun and a fume extraction torch is the air hose around it. You also have an air collection tube on the outside of the MIG gun, but the torch is still sized based on amperage and the part being welded. Whether it's a 15-foot or a 25-foot torch, welder access is still important.

You're still using the MIG gun based on what you need, not just because it's a fume extraction. So be sure based on the number of fume extraction torches that you stock adequate parts, are mindful of the additional parts you will need such as fume shrouds, and consider using a jacketing accessory like a closure around the hose to keep it from piercing and compromising suction power.

Also consider the length of the torch. Since introducing fume extraction torches, I’ve come across several scenarios where the manufacturing plant needed a 25-foot torch to weld with while extracting fumes. In one particular instance, a company was welding the inside of big hoppers with stainless steel, and the welding gun had to go over the top of the hopper and down hidden inside of it, and then had to run it from 25 foot gutters.

Always be mindful then of the part you have to weld and how far you have to reach. There's no difference in a fume extraction torch from a regular MIG gun when it comes to it welding. Just be aware that the longer the fume extraction torch, the more possibility exists of lost suction because of restriction and the potential for hose damage.

What are the parameters?

Parameters for your welding gun refers to a few specific criteria:

- Amperage

- Gas mix

- Wire size

- Base metal

The amperage consideration is to determine whether a water-cooled setup is a better option. If the process calls for the welding gun to exceed 340 amp at 60% duty cycle, at that point a water-cooled fume extraction torch is recommended. If air-cooled is something that has to be accommodated, then you’re looking at a heavier cable to reach amperage requirements. This means more strain on the welder and more stress on the cable and wear parts.

The primary reason to look at gas mix is because a high argon mix means the welding gun is likely running hot. If you are running with a hot gas mix, the recommendation may be to look at water-cooled fume extraction torches. The hot gas mix and higher parameters also means more fume is being produced, and this can necessitate a high-powered fume extraction system to capture the weld fume.

Wire size has an impact because fume extraction torches have limits to the size of wire it can support. Especially large wire diameters, like .094, are difficult to accommodate into a fume extraction torch because of the torch cable size restricting air flow through the hose. Wire sizes from .062 and lower can be built without any restriction or special consideration.

For base metal, whether the material is stainless or a manganese based material, or a manganese wire, is the primary consideration to make. That situation that requires using a W3 or an IFA certified fume extraction system to ensure the most damaging metal particles are captured and filtered in a safe manner that does not expose the welder.

Where is power available (and is it the right power)?

Power is one of the biggest problems I always run into. Many manufacturers don’t totally consider the power requirement for fume extraction in their facility. They always have a power drop for the welding machine, but that's the only 230 V single phase drop in the area.

Most high power fume extraction systems need to run on either 208 or 230 V. Lower powered units can run on 115 V power, but it sacrifices suction and performance for the fume extraction torch.

If there's not another power drop, sometimes you can place the unit farther away and add additional connection hose footage from the vacuum unit to the fume torch. Typically, fume extraction units come with 25 foot hoses, but you can use additional hose footage and fittings to go up to 50 feet. If you use a high powered, high flow fume extraction system, you can connect without sacrificing performance and get the desired results and effect.

Depending on the fume torch / extraction unit combination, you can go as far as a hundred feet away!

What is the status of the building?

Considerations of whether you own the facility, whether you can put in a central vac, and if you're going to do that many stations, you really should go for a central vacuum, but it's not always practical.

This is a question so few fume extraction solution providers or potential customers ask themselves. But, it has implications on what type of solutions you can use for fume extraction.

I had a customer that bought 14 fume extraction torches for welding stainless steel for the farm industry. They were a great candidate for a centralized fume extraction system based on the layout of the space, the number of torches required, and the budget they were willing to use to deal with fumes in their facility.

So what went wrong? They didn’t own the building, and the landlord would not allow them to install a central vacuum system. As a result, they had to go to all two torch fume extraction units. In the end, they utilized a solution that comprised 7 high powered portable vacuum units and 14 fume extraction torches to connect into them.

Building ownership isn’t the only deciding factor. Consider the other equipment in your facility. I had another experience with a customer who does own their building, but the facility is so big they can't use a central vac system. The high ceiling and overhead cranes made it an impractical solution for them. They too opted for portable units.

Remember, these questions are meant to guide you through making a smart and sound investment in a great solution that will make your facility cleaner, more productive, and more compliant.

There may be other questions you ponder as you begin your own process towards fume extraction. But, if you can answer the big ones that will make the decision-making process easier, you will be sure to land at a decision that meets your production and budgeting needs.