During my years as an Area Sales Manager, there was one question that I regularly got asked from our customers & welders:

"Danny, why am I going through an excessive amount of contact tips, gas nozzles, gas diffusors, tip adaptors & liners?"

The answer may be simple.

First check the following:

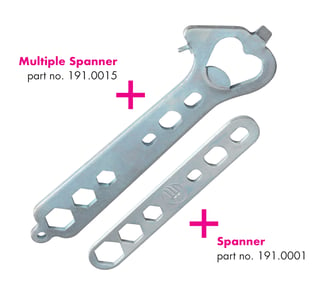

1. Is the tip adaptor & contact tip loose?

- Loose front end consumables will result in overheating & poor current transfer - make sure they are tight.

- Contact tips will look overheated (cooked).

- Diffusers will have a burnt look at the edges - the diffuser is wearing away or cracked

- Liners with signs of overheating ringlets may even look melted together.

Next step:

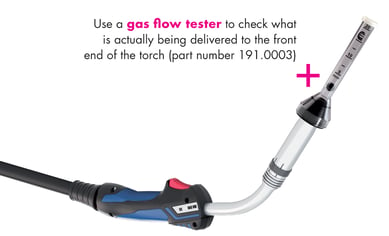

2. Is there a gas flow problem?

- Use a gas flow tester to check what is actually being delivered to the front end of the torch.

- Welding at a current of 300 amps will require between 16-18 litres per minute.

- MIG torches are gas cooled and need gas to not only protect the weld metal but gas also cools the front end consumables and increases their lifetime.

Regarding Liners:

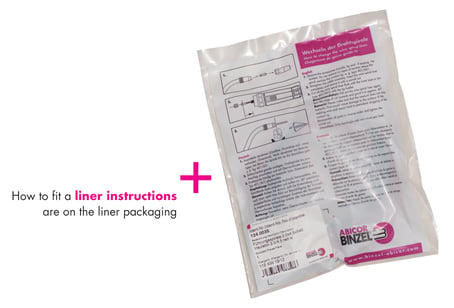

3. Liners must be fitted correctly to avoid wire feeding problems:

- Short or poorly fitted liners will result in wire burn backs. See fitting instructions on the liner packet.

- The liner should have a 45 degree angle at the front end so it fits centrally in the flute at the back of the contact tip.

- If you're using a torch with a removable neck - such as an ABIMIG A T or W T, consider using neck liners to make a quick neck change.

Follow these simple 'Care & Maintenance' tips and you'll see a significant reduction in your consumables usage.

/DS_Signature.png)

/LinkedIn_Profile_Picture.png)